What 3-A Certification Means for CIP Heat Exchangers

Only heat exchangers that pass rigorous third-party verification (TPV) by an authorized 3-A Certified Conformance Evaluator (CCE) may display the 3-A symbol — proving they meet or exceed all sanitary design criteria for Clean-in-Place applications.

- Third-Party Verification: Mandatory TPV by independent CCE.

- Product Contact Surface: Ra less than or equal to 32 microinch (0.8 micrometer) with mechanical polish.

- Full Drainability: No pockets, complete self-draining in installed position.

- Cleanable Seals: Elastomers must meet 3-A 18-03, no crevices.

- No Threads in Product Zone: All wetted connections must be sanitary clamp or weld.

- Inspectability: Removable parts or boroscope access required.

3-A Standards for CIP Heat Exchangers

The Gold Standard in Hygienic Design

3-A certified heat exchangers are engineered from the ground up for reliable Clean-in-Place performance, eliminating dead legs, crevices, and non-drainable areas that could harbor bacteria or prevent effective cleaning.

- Official 3-A Symbol authorization after TPV

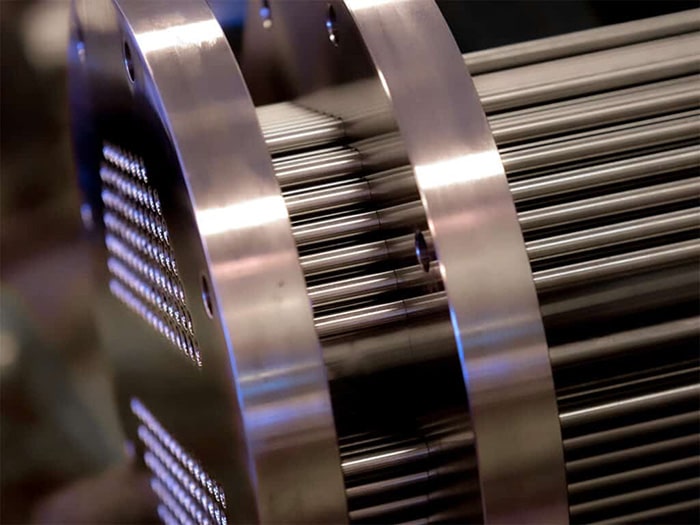

- 316L stainless steel product-contact surfaces

- Ra less than or equal to 32 microinch mechanical polish

- 100% self-draining design

- Sanitary clamp or welded connections only

- 3-A 18-03 compliant elastomers and seals

Why 3-A Certification is Required

Most dairy, egg, and food processors mandate 3-A certification for heat exchangers to ensure regulatory acceptance, audit readiness, and guaranteed cleanability. The 3-A symbol is recognized worldwide as proof of sanitary excellence.

Third-party verification eliminates self-declaration risk — only units that pass actual inspection earn the symbol.

Key 3-A Standards for Heat Exchangers

3-A 10- (Shell & Tube), 11- (Plate), 32- (Tubular), and 35- (Scraped Surface) define specific criteria for each exchanger type. All require TPV and compliance with 3-A general criteria 00-.

Surface Finish & Materials

Product contact surfaces must be 316L (or better) stainless steel with Ra less than or equal to 32 microinch and free of pits or cracks. Non-metallic parts must meet 3-A 18-03 (FDA & USDA compliant).

Drainability & Cleanability

Heat exchangers must be fully self-draining at normal shutdown angle. No horizontal tubes, no internal pockets, and all low points must drain completely.

Connections & Seals

Only sanitary clamp, weld-end, or approved fittings allowed in product zone. O-rings and gaskets must be removable, cleanable, and 3-A 18-03 certified.

Documentation Package

Every 3-A certified unit includes: Third-Party Verification report, 3-A symbol authorization, material certificates, surface finish reports, weld logs, and passivation certificate.

Why Choose 3-A Certified Exchangers

3-A certification is the only way to guarantee your heat exchanger will clean reliably, pass inspections, and protect product safety in regulated food and dairy applications.

Common FAQs

It means the equipment has been independently inspected and verified by a 3-A CCE to fully comply with the applicable 3-A Sanitary Standard.

Not legally required by FDA, but mandatory for most dairy plants and strongly recommended for any food-contact application.

Product contact surfaces must be less than or equal to 32 microinch (0.8 micrometer) Ra with mechanical polish and no imperfections visible at 10x.

Yes — when designed to 3-A 11- standard with double tubesheet (optional), proper gasketing, and verified drainability.

Certification is permanent for that exact design. Any modification invalidates the symbol unless re-verified.

Not required by 3-A 10-, but many plants specify them to prevent cross-contamination if a tube fails.