Plate & Frame CIP Exchangers

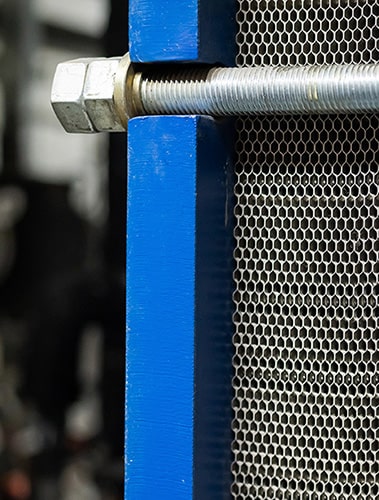

Plate and frame heat exchangers are the preferred choice for CIP applications where high efficiency, turbulence, and easy disassembly are essential. Their gasketed plate design creates narrow channels for intense cleaning action and complete drainage, making them ideal for low-viscosity, heat-sensitive, or low-fouling products in sanitary processes.

Plates alternate between product and utility fluids, with wide-gap options for particulates and high regeneration for energy savings. Polished product-contact surfaces, sanitary gaskets, and clip-on frames ensure compliance with 3-A, ASME-BPE, and FDA standards while supporting daily caustic, acid, and hot-water CIP protocols.

These exchangers excel in validated CIP with features like full drainability, easy plate inspection, and optional wide-gap plates for viscous fluids. They provide superior turbulence to remove residues like proteins, sugars, and minerals common in food, dairy, and biotech lines.

Configuration

Plate Count:

10 to 600+

Frame Size:

Up to 48" ports

Code:

ASME / 3-A / BPE

CIP-Optimized Features

- High Turbulence & Low Fouling

- Full Drainability & Easy Access

- Polished Plates (Ra = 32)

- Food-Grade Gaskets (EPDM/NBR)

- Sanitary Clamp Connections

- Wide-Gap for Particulates

- Clip-On Frame for Maintenance

- 3-A TPV & ASME Certification

Plate & Frame Heat Exchangers Optimized for CIP Applications

In CIP-intensive industries like dairy, food, beverage, and biotech, plate and frame exchangers provide superior efficiency and cleanability for heating, cooling, and pasteurization while supporting aggressive daily cleaning cycles.

Why Choose Plate & Frame for CIP

Plate and frame designs excel in CIP due to high turbulence in narrow channels, complete drainability, and easy opening for inspection. Wide-gap plates handle particulates without clogging, while high regeneration saves energy. Gasketed construction allows quick maintenance, and polished plates with sanitary gaskets ensure no crevices for biofilm. They meet 3-A, ASME-BPE, and PMO standards for validated cleaning in milk, juice, sauce, and pharma lines.

Standard CIP features include 316L plates, food-grade gaskets, sanitary ports, and vertical mounting for drainage. Options add electropolish (Ra = 15 µin), wide-gap channels, CIP connections, and third-party verification (TPV) for regulatory compliance.

CIP Design Advantages

Key CIP advantages: intense turbulence scours plate surfaces, full drainability prevents residuals, easy frame opening for visual checks, and gasket replacement without special tools. These features make plate and frame ideal for heat-sensitive or low-fouling products requiring frequent, validated CIP cycles.

CIP Applications

SANITARY CIP

Milk & Dairy

Plate & frame exchangers optimized for high-efficiency CIP in milk pasteurization, yogurt cooling, and dairy processes.

+ Learn More

BEVERAGE

Food & Beverage

Plate & frame exchangers ideal for juice, sauce, and beverage CIP with high turbulence and fast cleaning.

+ Learn More

DAIRY

Pharma & Biotech

Plate & frame exchangers for precise CIP/SIP in buffer prep, media heating, and biotech fluid processing.

+ Learn More