CIP Heat Exchangers for Emulsion Mixer Vessel Cleaning

Emulsion mixer vessels use high-shear agitators that trap thickeners, oils, and surfactants in hard-to-reach areas. Our sanitary CIP heat exchangers provide optimized hot water and chemical circulation with spray-ball support — delivering thorough removal of viscous residues, preventing phase separation risks, and enabling safe fragrance or active switches.

Key Emulsion Mixer Vessel CIP Applications

- High-Shear Agitator Cleaning: Targeted hot caustic flow dissolves emulsifiers and waxes from blades, shafts, and baffles.

- Hot Water Rinse Cycles: 185°F+ water circulation removes loose residues and prepares for final sanitization.

- Acid Neutralization: Controlled acid loops eliminate mineral deposits and neutralize caustic in vessel crevices.

- Spray Ball Optimization: Temperature-specific solutions maximize wetting and scouring of vessel interior surfaces.

- Active Ingredient Changeover: Validated CIP removes peptides, vitamins, and actives for clean batch transitions.

- Microbial & Residue Control: Ensures zero bioburden and emulsifier carryover with riboflavin-tested coverage.

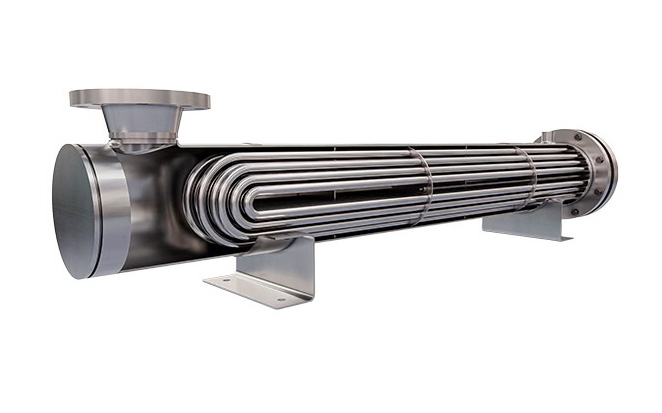

Shell & Tube

CIP Emulsion Exchangers

- Robust for Viscous Emulsions

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Emulsion Exchangers

- High Turbulence Efficiency

- Wide-Gap for Thickeners

- Fast CIP Changeover

The Critical Role of Sanitary CIP Heat Exchangers in Emulsion Mixer Vessel Cleaning

Emulsion mixer vessels with high-shear agitators trap thickeners and oils in baffles and seals, risking separation and contamination in subsequent batches. Inadequate cleaning compromises emulsion stability and product safety.

Our sanitary exchangers supply optimized chemical and water temperatures for effective scouring — removing stubborn emulsifiers, ensuring vessel hygiene, and supporting seamless switches between formulations.

A skincare manufacturer resolved batch instability after using our turbulence-enhanced systems. A cosmetics producer shortened vessel downtime 55% with our rapid-response exchangers.

With polished surfaces, full coverage validation, and reliable performance, our CIP heat exchangers guarantee pristine emulsion mixer vessels batch after batch.