CIP Heat Exchangers for All Process Equipment

Every piece of process equipment pumps, valves, tanks, homogenizers, fillers, and pipelines must be perfectly cleanable without disassembly. Our fully sanitary CIP heat exchangers supply the exact temperature, flow, and chemistry needed for validated cleaning across the entire plant, eliminating Listeria, Salmonella, allergens, and product residues while maximizing uptime and compliance.

Critical General Equipment CIP Applications

- Centrifugal Pump Impellers: High-velocity caustic/acid circulation through tight impeller clearances with fully CIP-capable, low-dead-volume exchangers.

- Fermentation Tank Sterilization: 185195°F hot water and chemical loops for complete interior sanitization of beer, yogurt, and biotech tanks.

- High-Pressure Homogenizers: Aggressive CIP of 2000+ bar valves and seals using sanitary exchangers resistant to extreme pressure and chemistry.

- Process Pipeline Cleaning: Long-distance, high-turbulence CIP of transfer lines with temperature-controlled caustic, acid, and rinse water.

- Spray Ball & Tank Systems: Supplies correctly heated solutions for full wetting coverage and validated riboflavin removal in vessels.

- Valve Clusters & Manifolds: Complex routing cleaned with precise temperature and flow from dedicated sanitary CIP exchangers.

- Filler Bowls & Nozzles: Daily hot water and chemical sanitization of high-speed filling heads with zero-residue exchangers.

- Allergen & Flavor Changeover: Complete removal of dairy, nuts, gluten, and flavors between runs using validated CIP protocols.

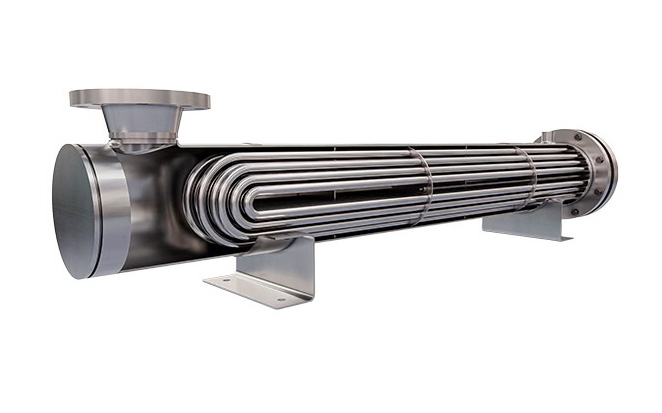

Shell & Tube

CIP General Exchangers

- Ideal for Hot Water Sets

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP General Exchangers

- High Regeneration Efficiency

- Compact & Fast Response

- Easy Inspection & CIP

Tube-in-Tube

CIP General Exchangers

- Perfect for Viscous Fluids

- Excellent Protein Removal

- Superior CIP Performance

The Critical Role of Sanitary CIP Heat Exchangers in General Process Equipment

Every piece of process equipment centrifugal pumps, positive-displacement pumps, mix-proof valve clusters, high-pressure homogenizers, fermentation and storage tanks, aseptic fillers, long transfer pipelines, and spray-ball systems must be 100 % cleanable without disassembly. Non-CIP-capable or poorly designed heat exchangers quickly become permanent harbors for Listeria monocytogenes, Salmonella, Pseudomonas, allergens, and product residues, leading to persistent contamination, off-flavors, shortened shelf life, regulatory non-conformances, and costly recalls.

Our sanitary CIP heat exchangers eliminate these risks at the source. Built with electropolished 316L stainless steel surfaces (Ra = 32 ΅in, many = 20 ΅in), complete self-draining geometry, zero dead legs (L/D = 2:1), and full-bore sanitary connections, they withstand the most aggressive daily caustic, phosphoric/nitric acid, and 195300 °F hot-water/steam cycles without corrosion or degradation.

They deliver the precise temperature, flow rate, and turbulence required for validated cleaning of even the most difficult equipment: impeller eye of centrifugal pumps, valve plug sealing surfaces, homogenizer second-stage valves, tank top ribs, and long horizontal pipelines. Double-tubesheet designs prevent cross-contamination between product and utility sides, while high-regeneration plate units save energy and water during extended CIP programs.

Real-world results prove the difference. A global dairy eliminated years of persistent biofilm in 300-bar homogenizers after installing our double-tubesheet exchangers. A multinational beverage giant reduced plant-wide CIP time 55 % and water consumption 40 % using our high-efficiency plate systems for pipelines, fillers, and carbonators. A leading infant-formula producer achieved zero spore-former issues and 90-day continuous runs with our fully validated tubular systems.

Backed by third-party verified 3-A TPV certification, riboflavin coverage testing, ATP/swab validation, complete material traceability, weld logs, and decades of proven performance in the most demanding food, dairy, beverage, and pharma plants worldwide, our CIP heat exchangers are the universal, future-proof foundation for safe, efficient, audit-ready cleaning of all process equipment today and for years to come.