Key Advantages of Clean-in-Place Systems

CIP transforms cleaning from a slow, labor-intensive manual task into a fast, validated, and automated process that consistently meets the highest hygienic standards while reducing operating costs and environmental impact.

- Reduced Downtime: Cleaning cycles complete in 30-90 minutes vs hours of manual teardown.

- Improved Food Safety: Eliminates human error and cross-contamination risks.

- Worker Safety: No confined-space entry or exposure to hot chemicals.

- Water & Chemical Savings: Recovery systems cut consumption by 30-70%.

- Consistent Results: PLC automation ensures every cycle meets validated parameters.

- Lower Labor Costs: Reduces cleaning crew size by up to 75%.

Why Choose Clean-in-Place?

Proven Benefits for Hygienic Processing

CIP systems deliver superior cleaning performance while slashing operating costs, improving safety, and maximizing production time — making them the industry standard for any plant requiring frequent, reliable Sanitization.

- Up to 75% faster cleaning than manual methods

- 30-70% reduction in water and chemical usage

- Eliminates confined-space hazards and chemical exposure

- Provides audit-ready documentation and validation

- Prevents allergen and microbial cross-contamination

- Extends equipment life through gentler, controlled cleaning

Major Advantages of CIP Systems

Modern CIP delivers measurable ROI within 12-24 months through reduced labor, utilities, and downtime while ensuring compliance with FDA, USDA, and 3-A standards. Recovery and automation features make it both cost-effective and sustainable.

Plants using CIP typically achieve higher overall equipment effectiveness (OEE) thanks to shorter changeovers and fewer quality holds.

Increased Production Uptime

Cleaning cycles finish in under 90 minutes, allowing more production runs per shift. Automated sequencing eliminates waiting time between steps.

Enhanced Food Safety & Compliance

Consistent, monitored parameters prevent under-cleaning. Conductivity and flow logging provide proof of effective Sanitization for regulators and auditors.

Worker Safety Improvements

Operators stay outside vessels — no climbing ladders, no manual scrubbing with caustic at 180 degrees Fahrenheit, and no risk of falling or chemical burns.

Resource Efficiency

Multi-tank recovery systems reuse rinse water as pre-rinse and maintain caustic/acid strength for weeks, dramatically lowering water, sewer, and chemical costs.

Labor Savings

One operator oversees multiple CIP circuits vs entire crews needed for manual cleaning. Labor savings alone often justify the investment.

Why CIP is the Industry Standard

Any hygienic process requiring daily or batch-to-batch cleaning benefits from CIP. It is essential for dairy, brewery, beverage, prepared foods, and pharmaceutical manufacturing.

Common FAQs

CIP typically reduces cleaning time by 60-75%. A process line that takes 4-6 hours to clean manually can be cleaned in 45-90 minutes with CIP.

Recovery CIP systems save 30-70% on water and chemicals compared to single-use or manual methods by reusing rinse water and detergent solutions.

Yes — CIP eliminates confined-space entry, manual handling of hot caustic, and physical scrubbing. Operators monitor from a control panel.

Yes — automated control of time, temperature, concentration, and flow ensures every cycle meets validated parameters, reducing risk of under-cleaning.

Most plants achieve payback in 12-24 months through labor savings, reduced utilities, and increased production time.

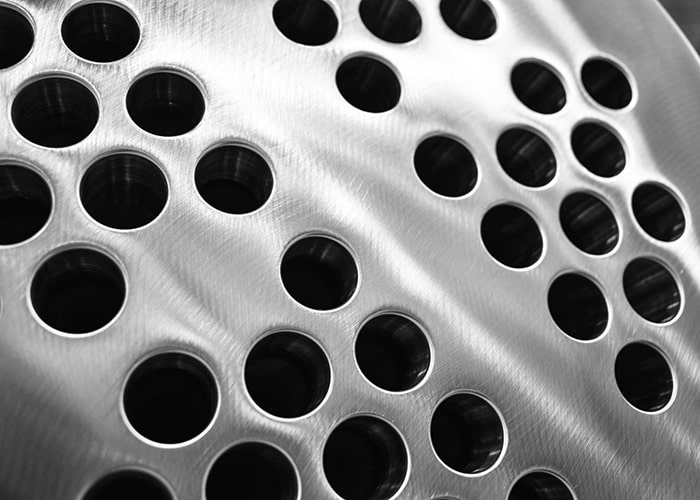

Yes — properly designed sanitary heat exchangers (plate, shell-and-tube, scraped-surface) are fully CIP-able when built with no dead legs and adequate flow.