CIP Heat Exchangers for High Pressure Homogenizer Cleaning

High-pressure homogenizers create extreme shear and heat, causing severe protein burn-on in valve seats and impact rings. Our fully sanitary CIP heat exchangers supply precise hot caustic, acid, and rinse temperatures with high-velocity flow — removing burnt milk, ensuring validated cleaning, and preventing Listeria in dairy, plant-based, and beverage applications.

Critical High Pressure Homogenizer CIP Applications

- First & Second Stage Valves: High-velocity caustic at 185°F+ dissolves burnt protein from valve seats and impact rings in 2000+ bar systems.

- Hot Water Sanitization: 195°F+ loops for daily sterilization of homogenizer block, pistons, and seals with zero dead legs.

- Acid Mineral Removal: Heated phosphoric/nitric acid circulation removes milkstone and calcium deposits from high-pressure zones.

- Plant-Based & Dairy Changeover: Full CIP eliminates almond, oat, or milk residues for zero allergen cross-contact.

- Aseptic Homogenizers: Sterile CIP with 300°F+ hot water for UHT lines using double-tubesheet, fully drainable exchangers.

- Validation & Testing: Riboflavin and ATP confirmation of 100 % coverage in valve seats and high-pressure zones.

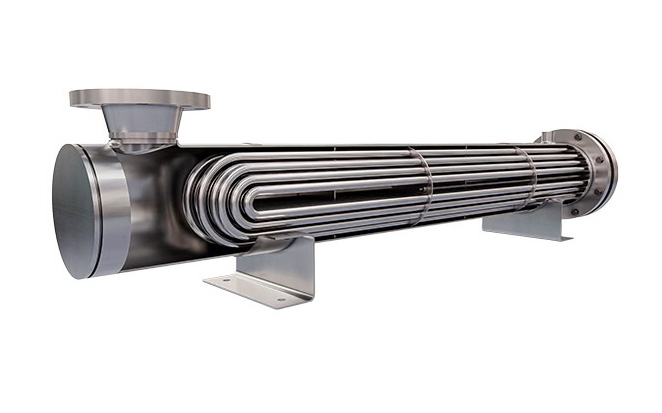

Shell & Tube

CIP Homogenizer Exchangers

- Double Tubesheet Protection

- Ideal for Hot Water Sets

- Fully Drainable Design

Plate & Frame

CIP Homogenizer Exchangers

- High Regeneration Efficiency

- Fast Caustic Heating

- Easy Inspection & CIP

The Critical Role of Sanitary CIP Heat Exchangers in High Pressure Homogenizer Cleaning

High-pressure homogenizers are the most difficult equipment to clean — extreme pressure and shear cause severe protein burn-on in valve seats and impact rings. Non-CIP-capable exchangers leave permanent Listeria and allergen sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 µin), full drainability, and proven resistance to daily caustic, acid, and 195°F+ cycles — delivering the exact temperature and velocity for validated cleaning of even 300-bar systems.

A global dairy eliminated persistent Listeria in 250-bar homogenizers after installing our double-tubesheet hot water systems. A plant-based milk leader reduced CIP time 55% and achieved zero allergen carryover with our high-efficiency plate exchangers.

With 3-A TPV certification, riboflavin & ATP validation, and decades of performance worldwide, our CIP heat exchangers are the trusted solution for safe, reliable high-pressure homogenizer cleaning.