CIP Heat Exchangers for Coffee Processing Equipment

The explosive growth of ready-to-drink coffee requires ultra-hygienic, fully CIP-capable heat exchangers to safely pasteurize or sterilize cold brew, nitro coffee, coffee-milk blends, and espresso concentrates while preserving delicate roasted flavor notes and preventing microbial spoilage.

Key Coffee Processing Applications

- Cold Brew Pasteurization: Gentle HTST or UHT treatment of filtered cold brew to achieve commercial sterility.

- Nitro Coffee Safety: Flash pasteurization before nitrogen infusion to eliminate yeast and bacteria.

- Canned Latte & Mocha: Thermal processing of dairy- or plant-based coffee beverages for hot-fill or aseptic lines.

- Coffee Concentrate: Safe sterilization of high-solids extract for shelf-stable reconstitution.

- Flash Chilling: Rapid post-extraction cooling to lock in fresh-roasted flavor before packaging.

- Flavor Changeover: Complete CIP removes coffee oils, milk proteins, and flavor residues between runs.

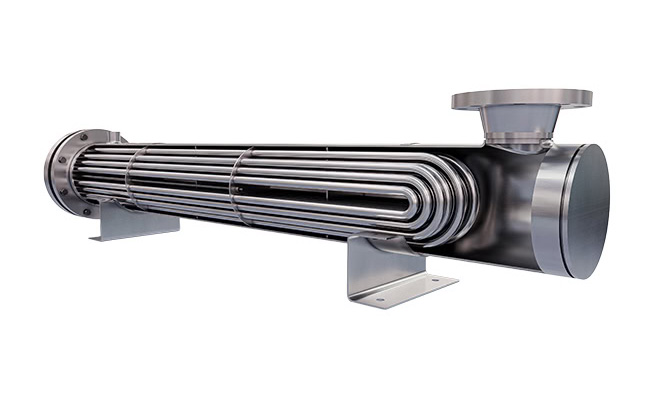

Shell & Tube

CIP Coffee Exchangers

- Double Tubesheet for Dairy Blends

- Ideal for Steam & Hot Water Sets

- Fully Drainable & 3-A Certified

Plate & Frame

CIP Coffee Exchangers

- High Regeneration Efficiency

- Precise Temperature Control

- Fast CIP & Flavor Changeover

Why Sanitary CIP Heat Exchangers Are Essential in Coffee Processing Equipment

Coffee beverages — especially those containing milk, oat, almond, or sugar — are highly susceptible to yeast, mold, and bacterial spoilage. Without fully CIP-capable heat exchangers, flavor carryover and microbial risk increase dramatically during high-speed RTD production.

Our sanitary exchangers deliver validated pasteurization or sterilization while preserving the delicate roasted coffee notes consumers expect. Polished 316L surfaces, no dead legs, and full drainability enable aggressive CIP cycles that remove coffee oils, milk proteins, and flavor residues in minutes — ensuring zero carryover when switching from black cold brew to vanilla latte.

A leading nitro coffee brand eliminated spoilage recalls and achieved 12-month shelf life using our plate pasteurizers. A global canned coffee producer reduced CIP time by 60% and increased line uptime with our double-tubesheet shell & tube systems.

With riboflavin-validated cleanability, 3-A certification where required, and proven performance in the world’s largest coffee plants, our CIP heat exchangers are the trusted choice for safe, flavorful, and profitable ready-to-drink coffee production.