CIP Heat Exchangers for Egg Liquid Pasteurization Lines

Liquid egg is one of the most protein-fouling products and carries high Salmonella risk. Our 3-A certified, fully drainable CIP heat exchangers deliver precise USDA-required temperatures, 95%+ regeneration, and validated cleaning — eliminating burn-on, preventing recontamination, and protecting whipping, binding, and emulsifying functionality.

Key Egg Liquid Pasteurization Applications

- Whole Egg Pasteurization: Precise 140–149°F hold with 95%+ regeneration and low-shear plate or tubular systems to achieve Salmonella kill while preserving coagulation and emulsification.

- Egg Yolk & High-Fat Blends: Higher temperature processing of high-fat yolk and blends using anti-fouling corrugated tube exchangers with validated CIP for complete protein removal.

- Egg White & Albumen: Ultra-gentle heating to protect foaming and gelling properties while delivering full Salmonella log reduction with low-shear, fully CIP-capable sanitary exchangers.

- Salted/Sugared Egg: Handles 10–45% added salt or sugar high-solids products with fully CIP-capable, high-viscosity designs proven for zero burn-on and complete residue removal.

- Hot Water Sets: Supplies 185–195°F closed-loop hot water for daily line, tank, and filler sanitization with zero dead legs, riboflavin-validated coverage, and full microbial kill.

- Flavor & Allergen Changeover: Complete validated CIP removes residual egg protein, sugar, salt, and additives between runs for zero allergen carryover and perfect product separation.

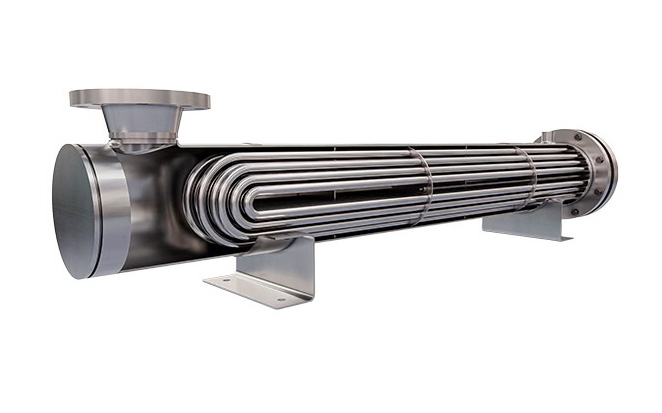

Shell & Tube

CIP Egg Exchangers

- Corrugated for High Solids

- Ideal for Salted/Sugared

- Fully Drainable & 3-A TPV

Plate & Frame

CIP Egg Exchangers

- 95%+ Regeneration Efficiency

- Low-Shear Protein Protection

- Riboflavin & Salmonella Validated

Tube-in-Tube

CIP Egg Exchangers

- Perfect for Sugared Yolk

- High-Solids Anti-Fouling

- Excellent CIP Cleanability

The Critical Role of Sanitary CIP Heat Exchangers in Egg Liquid Pasteurization Lines

Liquid egg products are among the most challenging — extreme protein fouling, high Salmonella risk, and strict USDA temperature/time requirements. Non-CIP-capable exchangers quickly develop burn-on and become permanent contamination sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 µin), full drainability, low-shear geometry, and proven resistance to daily caustic, phosphoric acid, and 195°F+ cycles — delivering validated Salmonella kill while preserving foaming, coagulation, and emulsification properties.

A leading U.S. egg processor eliminated recalls and achieved 30-day continuous runs after installing our high-regeneration plate systems. A global bakery supplier reduced CIP time 60% and maintained perfect functionality with our corrugated tube exchangers for salted yolk.

With 3-A TPV certification, riboflavin & Salmonella validation, full traceability, and decades of performance in the world’s largest egg plants, our CIP heat exchangers are the trusted standard for safe, functional, and profitable liquid egg pasteurization.