CIP Heat Exchangers for Fruit Puree Pasteurizer CIP

Fruit purees (mango, strawberry, banana, apple, etc.) are thick, fibrous, and sugar-rich — perfect for mold and yeast growth. Our fully sanitary, CIP-capable heat exchangers deliver gentle thermal treatment, high regeneration, and validated cleaning — eliminating burn-on, preserving natural color/flavor, and preventing spoilage in baby food, yogurt fillings, and bakery applications.

Key Fruit Puree Pasteurizer CIP Applications

- High-Particulate Purees: Handles mango, guava, peach with pieces up to 15 mm using wide-gap plate or tube-in-tube exchangers for gentle processing and complete CIP cleanability.

- Hot Fill & Aseptic: Precise 185–205°F heating for natural hot-fill preservation or full UHT sterilization before aseptic filling with validated microbial kill and CIP performance.

- Baby Food Purees: Ultra-gentle low-shear pasteurization and cooling to retain vitamins, color, and fresh flavor while achieving commercial sterility in sensitive infant products.

- Yogurt Fruit Prep: Dedicated heating and rapid cooling of fruit bases before yogurt addition using fully sanitary exchangers with proven flavor and allergen removal during CIP.

- Hot Water Sets: Supplies 195°F+ closed-loop hot water for daily line, tank, filler, and pump sanitization with zero dead legs and riboflavin-validated full wetting coverage.

- Flavor Changeover: Full validated CIP removes seeds, fibers, sugars, and natural colors between strawberry, mango, and berry runs for zero carryover and perfect flavor separation.

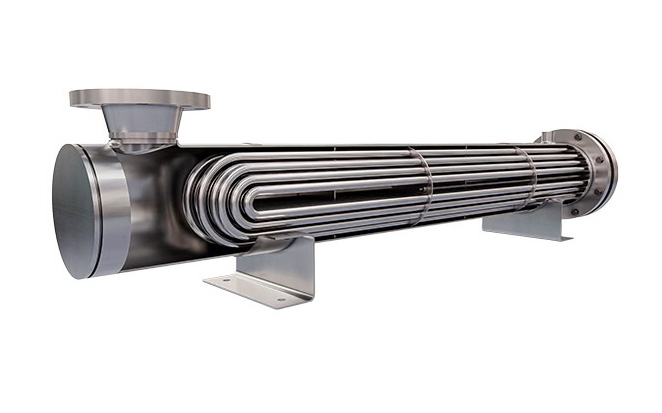

Shell & Tube

CIP Puree Exchangers

- Corrugated for High Solids

- Ideal for Hot Water Sets

- Fully Drainable & 3-A

Plate & Frame

CIP Puree Exchangers

- Wide-Gap for Seeds & Pulp

- High Regeneration Efficiency

- Fast CIP & Flavor Change

The Critical Role of Sanitary CIP Heat Exchangers in Fruit Puree Pasteurizer CIP

Fruit purees are thick, fibrous, and sugar-rich — ideal for heat-resistant molds, yeast, and severe fouling. Non-CIP-capable exchangers quickly clog with seeds, fibers, and burnt sugar, leading to spoilage and off-flavors in baby food, yogurt fillings, and bakery applications.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 µin), full drainability, wide-gap or corrugated designs, and proven resistance to aggressive caustic, acid, and 195°F+ cycles — delivering gentle pasteurization that preserves natural color, flavor, and vitamins.

A global baby food leader eliminated mold recalls and extended shelf life using our tube-in-tube systems for mango and banana puree. A major yogurt fruit-prep supplier reduced CIP time 55% and achieved zero flavor carryover with our wide-gap plate exchangers.

With 3-A certification where required, riboflavin-validated cleanability, full traceability, and decades of performance in the world’s largest puree plants, our CIP heat exchangers are the trusted standard for safe, high-quality fruit puree processing.