CIP/SIP Heat Exchangers for Antibiotic Fluid Sanitization

Antibiotic production involves complex fermentation broths with high risk of phage and bacterial contamination. Our ASME-BPE CIP/SIP heat exchangers deliver validated pure steam sterilization, WFI heating, and aggressive clean-in-place — eliminating residues, preventing resistance development, and ensuring sterile harvest, recovery, and purification lines.

Critical Antibiotic Fluid Sanitization Applications

- Fermentation Broth SIP: 135°C pure steam sterilization of mycelial or bacterial broth lines using double-tubesheet exchangers with full condensate removal.

- Harvest & Recovery Lines: Aggressive CIP of high-protein broth transfer lines with temperature-controlled caustic and acid for complete residue removal.

- Purification Skid CIP: Validated cleaning of chromatography and filtration systems with Ra = 15 µin electropolished exchangers.

- Phage Prevention: Complete SIP eliminates bacteriophage risk between batches with proven pure steam delivery and zero dead legs.

- Antibiotic Changeover: Full CIP/SIP removes beta-lactam or other residues for safe multi-product campaigns and allergen control.

- Endotoxin & Bioburden Control: Validated removal of pyrogens and microbes with riboflavin, endotoxin, and bioburden testing.

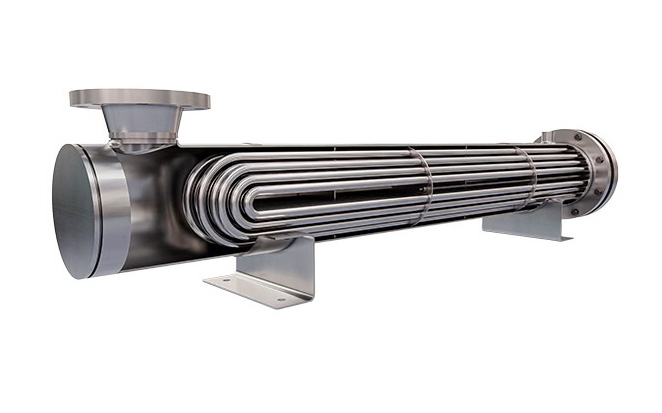

Shell & Tube

CIP/SIP Antibiotic Exchangers

- Double Tubesheet ASME-BPE

- Pure Steam Compatible

- Fully Drainable SIP

Plate & Frame

CIP/SIP Antibiotic Exchangers

- High Regeneration Efficiency

- Ra = 15 µin Electropolish

- Fast CIP & Validated SIP

The Critical Role of Sanitary CIP/SIP Heat Exchangers in Antibiotic Fluid Sanitization

Antibiotic production is highly sensitive to phage, bacterial contamination, and cross-product residues. Non-compliant exchangers risk resistance development and batch loss.

Our ASME-BPE exchangers eliminate that risk with electropolished 316L surfaces (Ra = 15 µin), double-tubesheet designs, full drainability, and proven resistance to pure steam SIP and aggressive CIP — delivering validated sterility for fermentation, harvest, and purification.

A global penicillin producer eliminated phage incidents after installing our pure steam SIP systems. A cephalosporin facility achieved zero cross-contamination with our high-regeneration plate exchangers.

With third-party validation, full traceability, and decades of performance in antibiotic plants, our CIP/SIP heat exchangers are the trusted standard for safe, compliant antibiotic production.