Why CIP Heat Exchangers Are Essential in Dairy Equipment Sanitization

Milk is the perfect growth medium for pathogens and spoilage organisms. Only fully sanitary, 3-A certified CIP heat exchangers guarantee validated cleaning and sterilization every cycle — preventing Listeria, Salmonella, milkstone, and biofilm while meeting the strictest Pasteurized Milk Ordinance (PMO), USDA, FDA, and HACCP requirements.

Critical Dairy Sanitization Applications

- Raw Milk Receiving & Preheating: Self-draining exchangers gently preheat raw milk while eliminating cold spots and ensuring full CIP cleanability.

- HTST & UHT Pasteurization: 3-A certified exchangers deliver precise PU with high regeneration, riboflavin-validated cleanability, and full drainability.

- Cream & Whey Processing: High-fat tolerant, double-tubesheet designs handle cream and whey without fouling or dead zones, with validated CIP.

- Yogurt & Fermented Products: Culture-safe heating/cooling with polished 316L surfaces and no dead legs, zero carryover risk during CIP.

- Cheese Milk Thermization: Gentle thermization minimizes protein damage while providing riboflavin-tested, fully drainable CIP performance.

- Ice Cream & Mix Systems: Rapid pasteurization and sub-zero cooling with scraped-surface or tube-in-tube designs and complete allergen removal.

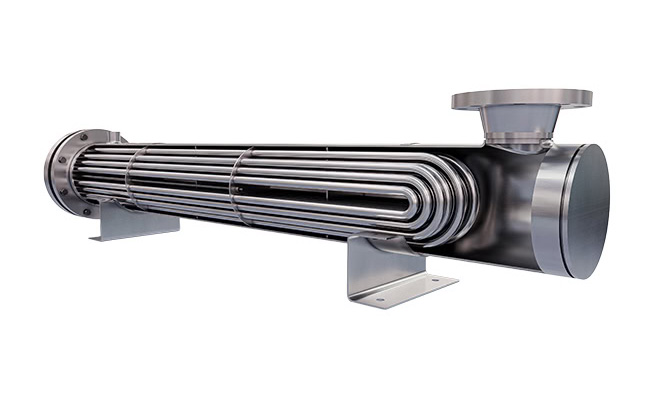

Shell & Tube

CIP Dairy Exchangers

- 3-A TPV & Double Tubesheet Options

- Ideal for Hot Water & Steam Sets

- Full Drainability & PMO Compliance

Plate & Frame

CIP Dairy Exchangers

- 95%+ Regeneration Efficiency

- Compact HTST Design

- Riboflavin & ATP Validated

Why CIP Heat Exchangers Are the Cornerstone of Dairy Equipment Sanitization

Dairy plants operate under zero tolerance for pathogens. A single biofilm event in a heat exchanger can trigger Listeria recalls, PMO violations, and plant shutdowns. Only fully sanitary, 3-A certified CIP heat exchangers eliminate that risk — delivering polished 316L surfaces (Ra = 32 µin), complete drainability, no dead legs, and proven resistance to daily caustic, acid, and 185°F+ hot water cycles.

Our exchangers are trusted in thousands of Grade A facilities worldwide because they guarantee validated log reductions, prevent milkstone buildup, and enable complete allergen removal between runs — all while preserving delicate milk proteins and flavor.

A major U.S. dairy eliminated chronic Listeria issues and passed every inspection with zero deviations after installing our double-tubesheet pasteurizers. A global cheese producer reduced CIP water usage by 50% and extended production runs using our high-regeneration plate systems.

With third-party verified (TPV) 3-A certification, riboflavin cleanability testing, full traceability, and decades of proven performance, our CIP heat exchangers are the industry standard for uncompromising dairy equipment Sanitization, regulatory confidence, and operational excellence.