Why CIP Heat Exchangers Are Essential in UHT Milk Pasteurizer & Line CIP

UHT lines run continuously for weeks and must achieve commercial sterility while preventing burn-on and spore survival. Only fully sanitary, 3-A certified CIP heat exchangers guarantee 95%+ regeneration, validated UHT temperatures, and complete cleanability — eliminating biofilm, milkstone, and spore-formers for safe ESL and shelf-stable milk.

Critical UHT Milk Pasteurizer & Line CIP Applications

- Indirect UHT Heating: Tubular or plate systems delivering 280–295°F for 2–6 seconds with high regeneration and full CIP capability.

- Direct Steam Injection/Infusion: Paired with sanitary flash cooling and vacuum systems using fully drainable exchangers.

- Hot Water Sets: Supplies 300°F+ closed-loop water for indirect heating sections with zero dead legs and validated sanitization.

- Regeneration Sections: 95%+ energy recovery with double tubesheet or plate designs that withstand daily caustic/acid CIP.

- Aseptic Surge Tanks: Pre- and post-UHT temperature control with fully sterile, CIP-capable exchangers.

- Line CIP Validation: Complete removal of burn-on milk proteins and minerals with riboflavin-tested, fully drainable exchangers.

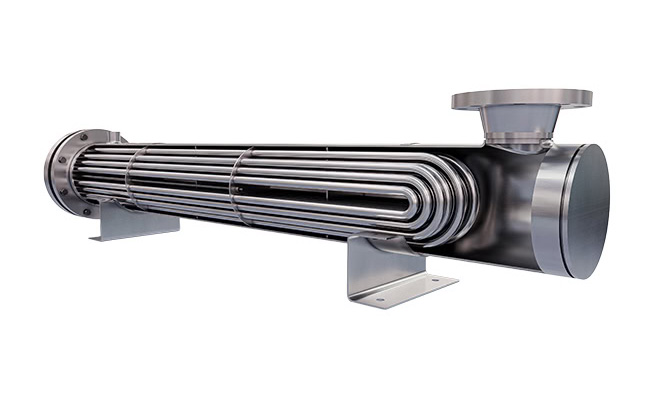

Shell & Tube

CIP UHT Exchangers

- Double Tubesheet Protection

- Ideal for High-Temp Hot Water

- Fully Drainable & 3-A TPV

Plate & Frame

CIP UHT Exchangers

- 95%+ Regeneration Efficiency

- Compact for ESL Lines

- Riboflavin & Spore Validated

Why CIP Heat Exchangers Are the Cornerstone of UHT Milk Pasteurizer & Line CIP

UHT lines run for weeks without stopping — any burn-on or biofilm in the heat exchanger becomes a spore factory that destroys commercial sterility. Only fully sanitary, 3-A certified CIP heat exchangers eliminate that risk — delivering polished 316L surfaces (Ra = 32 µin), 95%+ regeneration, complete drainability, and proven resistance to daily caustic, nitric acid, and 300°F+ hot water cycles.

Our exchangers are trusted in the world’s largest UHT milk plants because they guarantee zero burn-on, validated spore kill, and perfect line CIP — protecting shelf life from 6 to 12 months while minimizing energy and water use.

A global dairy giant eliminated spore recalls and achieved 90-day continuous runs after installing our double-tubesheet UHT systems. A major ESL milk producer reduced CIP chemical usage by 45% using our high-regeneration plate designs.

With third-party verified (TPV) 3-A certification, riboflavin and spore-log validation, full traceability, and decades of proven performance, our CIP heat exchangers are the industry standard for safe, efficient, and profitable UHT milk production.