Why CIP Heat Exchangers Are Essential in Butter Processing Equipment

High-fat cream and butter oil create perfect conditions for Listeria and milk fat residue buildup. Only fully sanitary, 3-A certified CIP heat exchangers guarantee complete removal of fat films and validated sterilization every cycle — preventing contamination while meeting strict PMO, USDA, FDA, and HACCP requirements.

Critical Butter Processing Applications

- Cream Pasteurization: Precise HTST treatment of 35–45% fat cream with high regeneration and full CIP cleanability.

- Cream Aging & Tempering: Accurate temperature control for crystallization with polished, drainable exchangers.

- Butter Oil & AMF Production: High-temperature sterilization of anhydrous milk fat with double-tubesheet protection.

- Churn Washing Systems: Hot water and caustic circulation for continuous butter churns with zero fat residue.

- Rework & Melting: Safe melting of butter rework and scraps with fully CIP-capable, high-fat tolerant designs.

- Packaging Line Support: Hot water sets for filler Sanitization and product temperature control before packing.

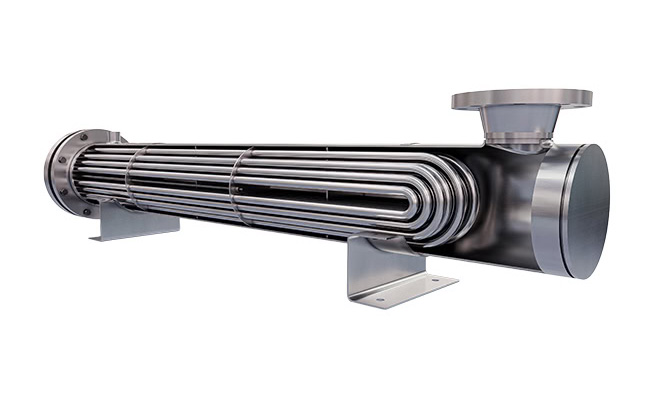

Shell & Tube

CIP Butter Exchangers

- Double Tubesheet for AMF Safety

- Ideal for High-Fat Cream & Oil

- Full Drainability & 3-A TPV

Plate & Frame

CIP Butter Exchangers

- High Regeneration Efficiency

- Wide-Gap for Cream Flow

- Riboflavin & ATP Validated

Why CIP Heat Exchangers Are the Cornerstone of Butter Processing Equipment Sanitization

Butter plants operate under extreme fat loads and strict Listeria control. A single fat film or dead zone in a heat exchanger can trigger recalls and PMO violations. Only fully sanitary, 3-A certified CIP heat exchangers eliminate that risk — delivering polished 316L surfaces (Ra = 32 µin), complete drainability, no dead legs, and proven resistance to daily caustic, acid, and 185°F+ hot water cycles.

Our exchangers are trusted in the world’s largest butter and AMF facilities because they guarantee total fat removal, validated log reductions, and zero allergen carryover between salted and unsalted runs — all while protecting delicate butter flavor.

A major European butter producer eliminated recurring Listeria issues and passed every audit with zero deviations after installing our double-tubesheet systems. A U.S. AMF plant reduced CIP time by 55% and extended production runs using our high-efficiency plate designs.

With third-party verified (TPV) 3-A certification, riboflavin cleanability testing, full traceability, and decades of proven performance, our CIP heat exchangers are the industry standard for uncompromising butter processing Sanitization, regulatory confidence, and operational excellence.