CIP Heat Exchangers for Pipeline Cleaning

Long transfer pipelines with bends, valves, and dead legs are notorious for incomplete cleaning and persistent contamination. Our fully sanitary CIP heat exchangers supply exact caustic, acid, and hot-water temperatures with high-velocity flow delivering turbulent cleaning (=5 ft/s), complete residue removal, and validated hygiene across entire plant piping systems.

Critical Pipeline Cleaning Applications

- Long-Distance Transfer Lines: High-velocity turbulent flow at correct temperature for complete cleaning of 100500 m pipelines with minimal dead legs.

- Hot Water Sanitization: 185195°F loops ensure microbial kill in all lines, including horizontal runs and low-point traps.

- Caustic Protein Removal: Heated caustic circulation dissolves milk, meat, and starch residues from pipe walls and weld seams.

- Acid Mineral & Milkstone: Phosphoric/nitric acid loops remove calcium, beerstone, and mineral deposits from long pipelines.

- Valve & Fitting Cleaning: Temperature-controlled CIP reaches mix-proof valves, T-pieces, and reducers for full sanitization.

- Allergen & Flavor Changeover: Complete removal of dairy, nuts, gluten, and flavors between runs for zero cross-contamination.

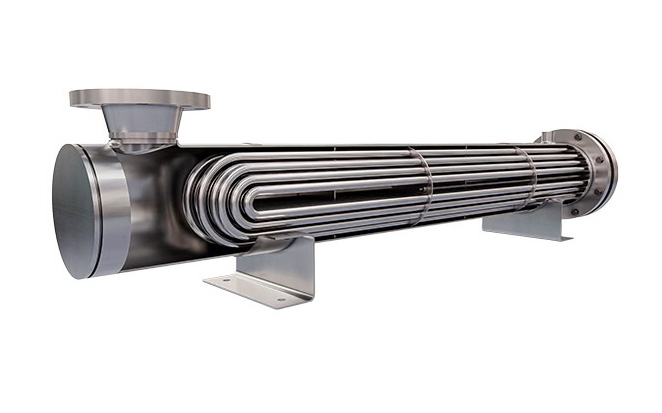

Shell & Tube

CIP Pipeline Exchangers

- Ideal for Hot Water Sets

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Pipeline Exchangers

- High Regeneration Efficiency

- Fast Caustic Heating

- Easy Inspection & CIP

The Critical Role of Sanitary CIP Heat Exchangers in Pipeline Cleaning

Process pipelines especially long horizontal runs, bends, and valve clusters are prime locations for incomplete cleaning, biofilm, and allergen carryover. Non-CIP-capable exchangers fail to deliver the required temperature and velocity, leaving permanent contamination sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 ΅in), full drainability, and proven resistance to daily caustic, acid, and 195°F+ cycles supplying exact temperature and flow for turbulent cleaning (=5 ft/s) across the entire piping system.

A global dairy reduced Listeria incidents to zero in 400 m transfer lines after installing our hot water CIP systems. A beverage giant cut pipeline CIP time 50% and achieved zero flavor carryover with our high-efficiency plate exchangers.

With riboflavin-validated coverage, full traceability, and decades of performance worldwide, our CIP heat exchangers are the trusted standard for safe, efficient, and compliant pipeline cleaning.