Why CIP Heat Exchangers Are Essential in Whey Protein Equipment CIP

Whey protein concentrates and isolates are extremely heat- and fouling-sensitive. Only fully sanitary, 3-A certified CIP heat exchangers prevent denaturation, burn-on, and biofilm while delivering precise pasteurization and evaporation pre-heating — protecting functionality, yield, and safety in high-value WPC/WPI production.

Critical Whey Protein Equipment CIP Applications

- Sweet/Acid Whey Pasteurization: Gentle HTST of cheese or casein whey using low-shear, fully CIP-capable plate or tubular exchangers.

- UF/DF Pre-Heating: Precise temperature control before membrane concentration with polished, fully drainable exchangers.

- Evaporator Feed Heating: High-solids pre-heating for MVR/TVR evaporators with anti-fouling corrugated tube designs.

- Spray Dryer Feed: Final heating of 35–80% concentrates with minimal residence time and validated CIP cleanability.

- Hot Water & CIP Sets: Supplies 185–210°F water and caustic/acid for membrane, evaporator, and dryer CIP circuits.

- Protein Fraction Changeover: Complete CIP removes WPC vs WPI residues and prevents allergen cross-contact.

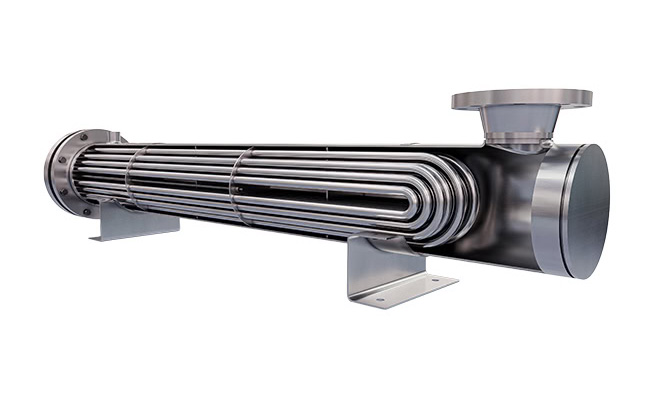

Shell & Tube

CIP Whey Exchangers

- Corrugated Tube Anti-Fouling

- Ideal for High-Solids Whey

- Fully Drainable & 3-A TPV

Plate & Frame

CIP Whey Exchangers

- High Regeneration Efficiency

- Low-Shear Protein Protection

- Riboflavin & Protein Validated

Why CIP Heat Exchangers Are the Cornerstone of Whey Protein Equipment CIP

Whey protein lines handle extremely fouling-prone, high-value liquids — any burn-on or residual protein becomes a denatured mess and microbial risk. Only fully sanitary, 3-A certified CIP heat exchangers eliminate that threat — delivering polished 316L surfaces (Ra = 32 µin), complete drainability, low-shear geometry, and proven resistance to daily caustic, phosphoric acid, and 200°F+ cycles.

Our exchangers protect whey functionality, maximize yield, and enable validated cleaning between WPC 35 and WPI 90 runs — critical for allergen control and product integrity.

A leading global WPI producer eliminated denaturation complaints and increased yield 3% using our low-shear plate pasteurizers. A major cheese plant reduced whey CIP time 55% and achieved zero spore counts with our corrugated tube evaporator pre-heaters.

With third-party verified (TPV) 3-A certification, riboflavin & protein recovery validation, full traceability, and decades of performance in the world’s top whey plants, our CIP heat exchangers are the gold standard for safe, high-yield whey protein production.