CIP Heat Exchangers for Cosmetic Lotion Processing

Lotion production involves complex oil-in-water emulsions sensitive to shear and temperature variation. Our sanitary CIP heat exchangers ensure uniform heating/cooling, stable viscosity, and thorough clean-in-place — vital for batch consistency, microbial control, and rapid fragrance or active ingredient changeovers in daily moisturizers and premium skincare.

Key Cosmetic Lotion Processing Applications

- Emulsion Heating: Controlled heating of oil and water phases for stable lotion formation with low-shear, sanitary exchangers.

- Active Ingredient Addition: Precise temperature maintenance during incorporation of vitamins, peptides, and botanicals.

- Post-Emulsion Cooling: Rapid, uniform cooling to set viscosity and prevent separation in finished lotions.

- Sunscreen Lotions: Even heating of UV filters and emollients with exchangers resistant to chemical cleaners.

- Hot Water CIP Loops: 185°F+ circulation for daily kettle, line, and pump sanitization with zero residue.

- Fragrance Changeover: Thorough CIP removes scents and colors for clean transitions between product variants.

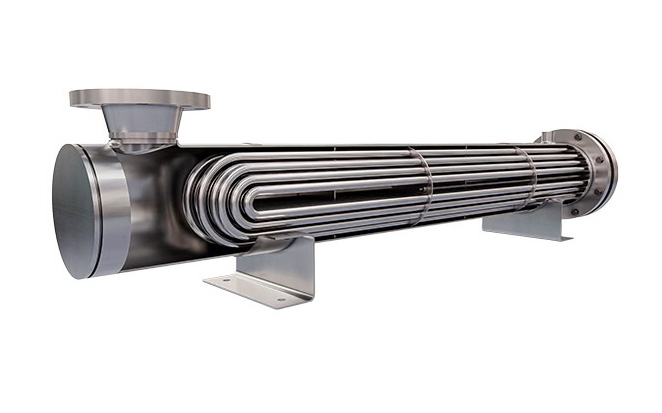

Shell & Tube

CIP Lotion Exchangers

- Robust for Viscous Lotions

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Lotion Exchangers

- High Efficiency Emulsion

- Wide-Gap for Thickeners

- Fast CIP Changeover

The Critical Role of Sanitary CIP Heat Exchangers in Cosmetic Lotion Processing

Lotion manufacturing relies on stable emulsions and frequent batch changes — any residue risks separation, contamination, or off-odors. Poorly cleanable exchangers threaten product quality and brand reputation.

Our sanitary exchangers deliver gentle, uniform temperature profiles for perfect emulsion formation while supporting aggressive CIP to remove waxes, oils, and thickeners — ensuring batch-to-batch consistency and microbial safety.

A premium skincare brand stabilized emulsions and eliminated separation issues using our precise plate systems. A mass-market lotion producer cut changeover downtime 60% with our wide-gap exchangers.

With polished surfaces, full drainability, and validated cleaning, our CIP heat exchangers are essential for high-quality, efficient cosmetic lotion production.