CIP Heat Exchangers for Cosmetics & Personal Care

Cosmetics and personal care manufacturing involves viscous emulsions, fragrances, and surfactants that require frequent cleaning to avoid contamination and carryover. Our sanitary CIP heat exchangers provide precise temperature control and complete clean-in-place removing residues, preventing microbial growth, and enabling rapid product changeovers while maintaining product stability and quality.

Critical Cosmetics & Personal Care CIP Applications

- Lotion & Cream Emulsions: Gentle heating and cooling of oil-in-water emulsions with fully CIP-capable exchangers for smooth texture and stability.

- Shampoo & Conditioner: Precise viscosity control and fragrance incorporation with high-turbulence exchangers that clean completely between batches.

- Gel & Toothpaste Processing: Heating of thick, abrasive gels with wide-gap or tube designs for easy residue removal and validated CIP.

- Sunscreen & SPF Formulas: Uniform heating of UV filters and emollients with sanitary exchangers resistant to chemical cleaners.

- Fragrance & Color Changeover: Complete CIP removes volatile scents and dyes for zero carryover between product runs.

- Allergen & Residue Control: Validated cleaning eliminates nuts, gluten, and other allergens with riboflavin-tested exchangers.

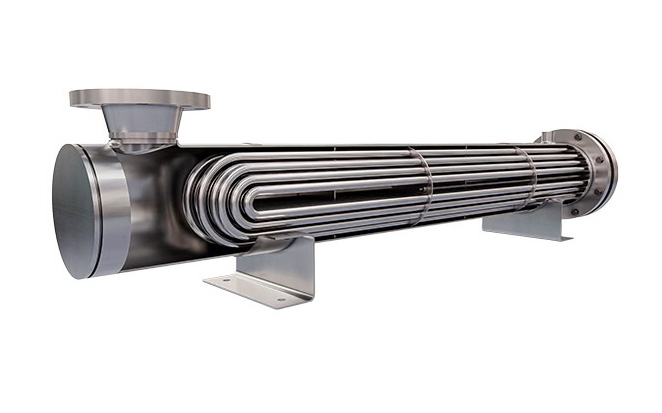

Shell & Tube

CIP Cosmetics Exchangers

- Robust for Viscous Products

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Cosmetics Exchangers

- High Turbulence Efficiency

- Wide-Gap for Emulsions

- Fast CIP Changeover

The Critical Role of Sanitary CIP Heat Exchangers in Cosmetics & Personal Care

Cosmetics and personal care production involves frequent changeovers and sensitive emulsions prone to contamination. Non-CIP-capable exchangers risk microbial growth and fragrance carryover.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 ΅in), full drainability, and proven resistance to daily caustic, acid, and hot-water cycles delivering gentle heating/cooling and validated cleaning for lotions, shampoos, and gels.

A leading cosmetics brand achieved zero fragrance carryover after installing our high-turbulence plate systems. A personal care manufacturer reduced CIP time 50% with our wide-gap exchangers for thick creams.

With riboflavin-validated cleanability, full traceability, and decades of performance worldwide, our CIP heat exchangers are the trusted standard for safe, efficient cosmetics production.