CIP Heat Exchangers for Tomato Paste Concentrator Cleaning

Tomato paste concentrators (MVR/TVR) run 30–70 Brix solids that cause severe fouling, burn-on, and microbial risk. Our fully sanitary CIP heat exchangers supply pre-heating, hot water sets, and aggressive clean-in-place — removing pulp, lycopene, and sugar residues while ensuring FDA/USDA compliance and maximum uptime.

Key Tomato Paste Concentrator Cleaning Applications

- Evaporator Pre-Heating: High-solids tomato feed pre-heating using corrugated tube exchangers engineered for minimal fouling and maximum heat transfer in viscous streams.

- Hot Water CIP Sets: Supplies 195–210°F closed-loop hot water for daily cleaning of evaporator, calandria, separators, and all product-contact surfaces.

- High-Brix Handling: Special anti-fouling corrugated or wide-gap designs proven for 60–70 Brix paste with complete pulp, seed, and skin removal during CIP.

- Condensate Recovery: Sanitary cooling and recovery of clean evaporator condensate using fully CIP-capable, polished, and drainable heat exchangers.

- Flavor & Grade Changeover: Complete validated CIP removes residual seeds, skins, sugars, and lycopene between different paste grades and campaigns.

- Hot Break vs Cold Break: Rapid, thorough CIP enables fast changeover between hot-break and cold-break processes without flavor or color carryover.

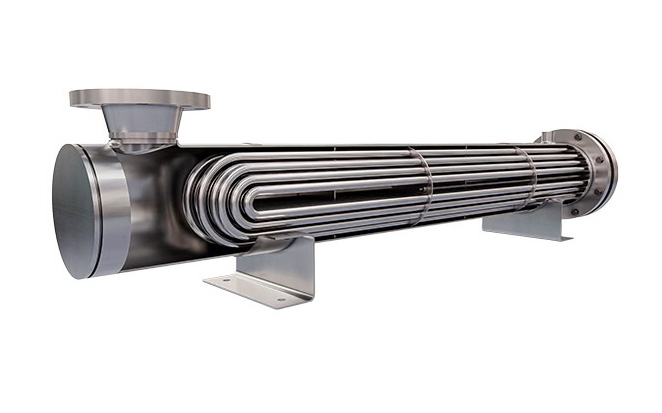

Shell & Tube

CIP Tomato Exchangers

- Corrugated for High Solids

- Ideal for Hot Water Sets

- Fully Drainable Design

Plate & Frame

CIP Tomato Exchangers

- Wide-Gap for Pulp & Seeds

- High Regeneration Efficiency

- Fast CIP & Validated

Tube-in-Tube

CIP Tomato Exchangers

- Perfect for High-Brix Paste

- Excellent Burn-On Removal

- Superior CIP Performance

The Critical Role of Sanitary CIP Heat Exchangers in Tomato Paste Concentrator Cleaning

Tomato paste concentrators are among the most fouling-intensive units — high Brix, pulp, and sugar create severe burn-on and microbial risk. Non-CIP-capable exchangers quickly become permanent contamination sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 µin), full drainability, corrugated or wide-gap designs, and proven resistance to aggressive caustic, acid, and 210°F+ cycles — delivering perfect cleaning between hot-break and cold-break campaigns.

A global tomato processor eliminated mold recalls and reduced CIP time 65% after installing our high-solids tube-in-tube systems. A leading Italian paste producer achieved zero flavor carryover and extended evaporator runs with our wide-gap plate pre-heaters.

With riboflavin-validated cleanability, full traceability, and decades of performance in the world’s largest tomato plants, our CIP heat exchangers are the trusted standard for safe, efficient, and compliant concentrator cleaning.