CIP Heat Exchangers for Sauce Cooking Kettle Sanitization

Cooking kettles for pasta sauce, cheese sauce, gravy, and condiments are notorious for burn-on and Listeria harborage. Our fully sanitary CIP heat exchangers supply jacket heating/cooling, hot water sets, and aggressive clean-in-place — removing starch, protein, and sugar residues while ensuring microbial safety and FDA/FSMA compliance.

Key Sauce Kettle Sanitization Applications

- Jacket Heating/Cooling: Precise steam or water jacket temperature control using fully CIP-capable shell & tube or plate exchangers for uniform cooking and rapid cooldown.

- Hot Water CIP Sets: Supplies 185–200°F closed-loop hot water for daily kettle jacket, agitator, and spray-ball sanitization with zero dead legs and validated kill.

- High-Starch Sauces: Handles thick cheese sauce, béchamel, and roux-based products with anti-fouling corrugated tube or wide-gap plate designs for easy cleaning.

- Tomato-Based Sauces: Acid-resistant exchangers remove burnt sugar and lycopene stains with proven caustic/acid CIP cycles for marinara, ketchup, and BBQ sauce.

- Scraped-Surface Prep: Pre-heating ultra-viscous bases before kettle transfer using easy-clean tube-in-tube or scraped-surface exchangers with full CIP capability.

- Flavor Changeover: Complete validated CIP removes spices, dairy, allergens, and color residues between batches for zero carryover and perfect flavor separation.

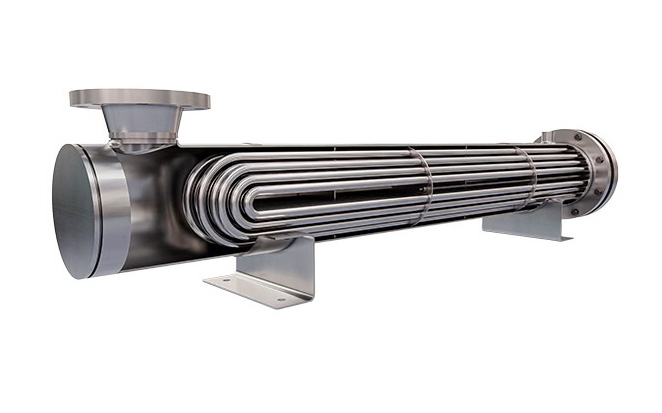

Shell & Tube

CIP Sauce Exchangers

- Ideal for Jacket Hot Water

- High-Pressure Steam Capable

- Fully Drainable Design

Plate & Frame

CIP Sauce Exchangers

- High Efficiency Heating

- Wide-Gap for Chunky Sauce

- Fast CIP & Validated

The Critical Role of Sanitary CIP Heat Exchangers in Sauce Cooking Kettle Sanitization

Sauce kettles are burn-on and Listeria hotspots — starch, protein, and sugar create perfect conditions for fouling and persistent contamination. Non-CIP-capable exchangers quickly become permanent pathogen sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 µin), full drainability, wide-gap or corrugated designs, and proven resistance to aggressive caustic, acid, and 200°F+ cycles — delivering perfect cleaning between tomato, cheese, gravy, and spicy varieties.

A leading pasta sauce producer eliminated Listeria recalls and reduced CIP time 60% after installing our jacket hot water systems. A major cheese sauce manufacturer achieved zero flavor carryover and 100% audit compliance with our high-viscosity tube-in-tube exchangers.

With riboflavin-validated cleanability, full traceability, and decades of performance in the world’s largest sauce plants, our CIP heat exchangers are the trusted standard for safe, efficient, and compliant kettle sanitization.