CIP Heat Exchangers for Centrifugal Pump Impeller Cleaning

Centrifugal pump impellers operate at high RPM with micron-level clearances perfect traps for biofilm, milkstone, and allergens. Our fully sanitary CIP heat exchangers supply the exact temperature, turbulence, and chemistry needed for validated cleaning of impeller eyes, vanes, and seals preventing Listeria harborage and ensuring pump hygiene without disassembly.

Critical Centrifugal Pump Impeller CIP Applications

- Impeller Eye & Front Shroud: High-velocity caustic circulation removes protein and fat films from the hardest-to-reach areas using temperature-controlled CIP supply.

- Rear Seal & Back Vanes: Heated acid loops dissolve milkstone and mineral deposits from seal faces and back vanes with fully drainable sanitary exchangers.

- Casing & Volute Cleaning: Precise 185195°F hot water and caustic delivery for complete removal of product residue from casing interior surfaces.

- Allergen & Flavor Changeover: Validated CIP removes dairy, soy, nut, and flavor residues between runs for zero cross-contamination risk.

- High-Fat Product Pumps: Handles cream, batter, and meat slurry pumps with anti-fouling designs and aggressive fat-dissolving CIP cycles.

- Pump Validation: Riboflavin and ATP testing confirms 100 % coverage of impeller, seal, and casing with temperature-controlled CIP supply.

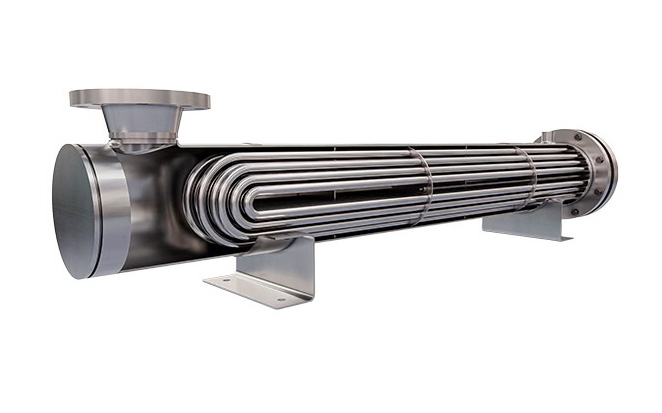

Shell & Tube

CIP Pump Exchangers

- Ideal for Hot Water Sets

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Pump Exchangers

- High Turbulence Cleaning

- Compact & Fast Response

- Easy Inspection & CIP

The Critical Role of Sanitary CIP Heat Exchangers in Centrifugal Pump Impeller Cleaning

Centrifugal pump impellers are among the toughest CIP challenges high-speed vanes, micron clearances, and seal faces trap proteins, fats, and microbes. Non-CIP-capable exchangers leave residual soil that becomes permanent Listeria and allergen sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 ΅in), full drainability, and proven resistance to daily caustic, acid, and 195°F+ cycles delivering the exact temperature and velocity needed for validated cleaning of impeller eyes, shrouds, and seals.

A major dairy eliminated persistent Listeria in cream pumps after installing our hot water CIP exchangers. A global beverage plant reduced pump CIP time 60% and achieved zero allergen carryover with our high-turbulence plate systems.

With 3-A certification, riboflavin & ATP validation, and decades of performance worldwide, our CIP heat exchangers are the trusted solution for safe, reliable centrifugal pump impeller cleaning.