CIP Heat Exchangers for Cream Batch Tank Sterilization

Cream batch tanks store high-fat product that rapidly develops biofilms and fat films. Our sanitary CIP heat exchangers provide controlled hot water, caustic, and acid delivery with full spray coverage — achieving validated sterilization, complete fat removal, and zero carryover between fresh, whipping, and cultured cream batches.

Key Cream Batch Tank Sterilization Applications

- Hot Water Sterilization: 185–195°F circulation with precise temperature control for microbial kill on tank walls, agitators, and outlets.

- Caustic Fat Dissolving: Heated caustic loops remove butterfat films and protein deposits from interior surfaces and spray devices.

- Acid Mineral Removal: Controlled acid circulation dissolves calcium and milkstone from tank fittings and low-point drains.

- Spray Ball Coverage: Temperature-optimized solutions ensure 100 % wetting and riboflavin-validated cleaning of all shadow areas.

- Cream Type Changeover: Thorough CIP eliminates residual fat levels between 18 %, 36 %, and 40 %+ cream batches.

- Listeria & Pathogen Control: Validated cycles achieve log reductions required for high-fat dairy storage tanks.

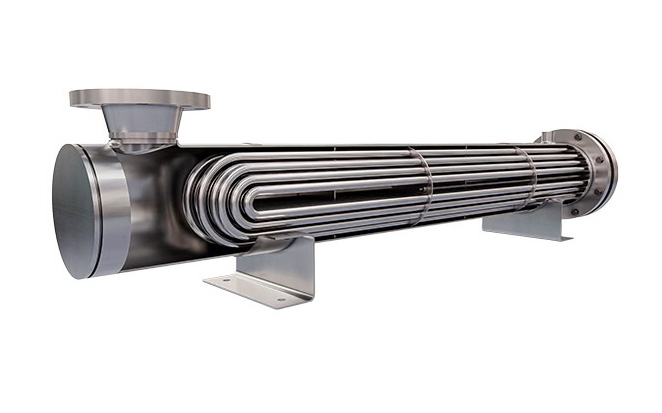

Shell & Tube

CIP Cream Tank Exchangers

- Ideal for Hot Water Sets

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Cream Tank Exchangers

- High Regeneration Efficiency

- Wide-Gap for High Fat

- Fast CIP & Validated

The Critical Role of Sanitary CIP Heat Exchangers in Cream Batch Tank Sterilization

Cream batch tanks store rich, high-fat product that quickly develops stubborn fat films and Listeria biofilms. Inadequate sterilization risks product spoilage and regulatory violations.

Our sanitary exchangers provide reliable hot water and chemical delivery with full spray coverage — achieving complete fat dissolution, validated microbial kill, and zero residue between batches.

A large whipping cream producer eliminated Listeria positives after implementing our hot water systems. A manufacturing cream facility reduced cleaning cycles 55% with our high-efficiency caustic heating exchangers.

With 3-A certification, riboflavin validation, and proven performance in cream storage, our CIP heat exchangers ensure safe, compliant cream batch tank sterilization.