CIP Heat Exchangers for Brewery Sanitization & Cleaning

Beer is a perfect growth medium for spoilage organisms like Lactobacillus, Pediococcus, and wild yeast. Our fully sanitary, CIP-capable heat exchangers enable aggressive cleaning and hot water/chemical sanitization — protecting wort chillers, bright tanks, and packaging lines while ensuring fast, reliable changeovers between beer styles.

Key Brewery Sanitization Applications

- Wort Chilling: Single- or two-stage rapid cooling with fully CIP-capable plate exchangers.

- Hot Water & CIP Sets: Supplies 185°F+ water and caustic for tank, line, and filler cleaning.

- Tunnel Pasteurization: Precise PU delivery for canned/bottled beer stability.

- Cold Block Glycol Loops: Maintains fermentation and brite tank temperatures with sanitary exchangers.

- Flash Pasteurization: Inline microbial kill for kegged or draft beer lines.

- Beer Style Changeover: Complete CIP removes hop resins, yeast, and flavor carryover.

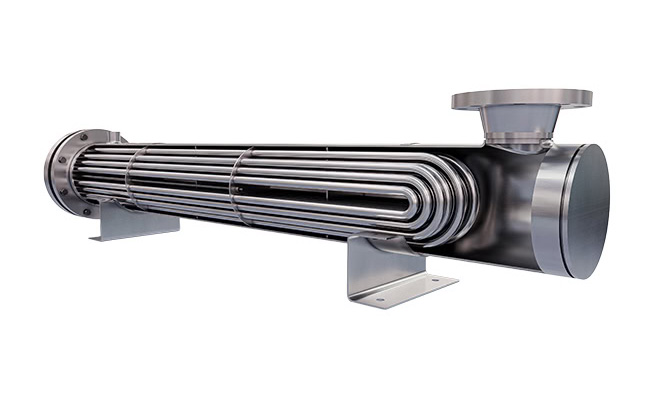

Shell & Tube

CIP Brewery Exchangers

- Robust for Hot Water & Steam

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Brewery Exchangers

- Fast Wort Cooling Response

- High Turbulence Cleaning

- Easy Inspection & Maintenance

Why Sanitary CIP Heat Exchangers Are Essential for Brewery Sanitization & Cleaning

Breweries face constant risk from beer-spoiling bacteria and wild yeast — especially in high-speed packaging and frequent style changeovers. Non-CIP-capable or poorly designed heat exchangers become permanent sources of contamination, leading to off-flavors, haze, and shortened shelf life.

Our fully sanitary exchangers eliminate that risk with polished 316L surfaces, no dead legs, full drainability, and aggressive CIP compatibility. They withstand daily caustic, acid, and 185°F+ hot water cycles — removing hop oils, trub, yeast, and protein deposits completely between brews.

A leading U.S. craft brewery eliminated recurring diacetyl issues and doubled production after installing our high-turbulence plate wort chillers. A major international lager brand reduced CIP time by 65% and achieved 100% clean filler audits using our double-tubesheet shell & tube systems.

With riboflavin-validated cleanability, proven performance in thousands of breweries worldwide, and designs trusted by the largest craft and macro brewers, our CIP heat exchangers are the gold standard for brewery sanitization, cleaning efficiency, and consistent beer quality.