Why CIP Heat Exchangers Are Critical for Safe Drink Production

From carbonated soft drinks and juices to RTD teas, energy drinks, and functional beverages, modern drink production demands validated microbial kill steps and zero risk of recontamination. Our fully sanitary, CIP-capable heat exchangers deliver precise thermal treatment and guaranteed cleanability — protecting consumers and your brand reputation.

Key Safety Applications

- Flash Pasteurization: Delivers exact PU values to destroy yeast, mold, and pathogens in juice, CSD, and RTD drinks.

- Hot Fill Safety: Heats sensitive beverages to 185–195°F for natural preservation without preservatives.

- Post-Mix Syrup Pasteurization: Eliminates Alicyclobacillus and heat-resistant molds in concentrated syrups.

- Cold Aseptic Filling Prep: Pre-pasteurizes product before sterile filling to extend shelf life.

- Carbonation Chilling: Rapidly cools water/syrup to improve CO2 absorption and prevent microbial growth.

- Flavor Changeover Safety: Full CIP eliminates residual allergens and microbes between runs.

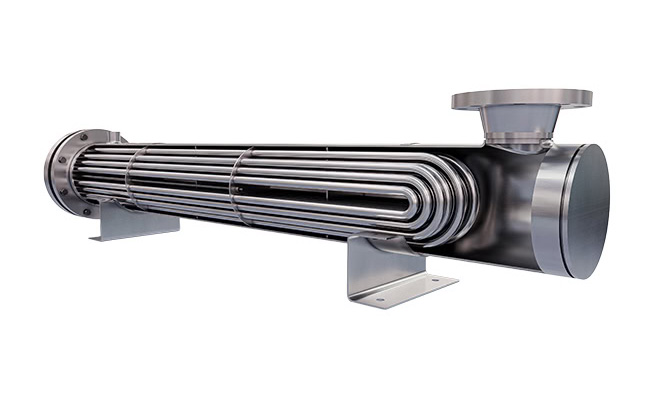

Shell & Tube

CIP Safety Exchangers

- Double Tubesheet Leak Protection

- Ideal for Hot Water & Steam Sets

- Fully Drainable & 3-A Certified

Plate & Frame

CIP Safety Exchangers

- High Regeneration & Energy Efficiency

- Precise PU Control & Logging

- Fast, Validated CIP Cycles

Why Sanitary CIP Heat Exchangers Are Essential for Safe Drink Production

Today’s consumers demand safe, preservative-free beverages — and regulators demand proof. Poorly designed or non-CIP-capable heat exchangers are the #1 cause of microbial recalls in juice, iced tea, sports drinks, and RTD products.

Our fully sanitary, 3-A compliant exchangers eliminate that risk with polished 316L surfaces, no dead legs, full drainability, and validated clean-in-place performance. They deliver exact pasteurization units (PU), prevent recontamination during cooling, and enable complete allergen removal between flavors — all with documented, audit-ready data.

A global iced tea producer eliminated spoilage outbreaks and achieved 180-day shelf life after installing our plate pasteurizers. A major energy drink brand passed every FDA inspection with zero deviations using our double-tubesheet shell & tube systems.

With riboflavin-tested cleanability, third-party verified designs, and proven performance in thousands of high-speed drink lines worldwide, our CIP heat exchangers are the trusted foundation for safe, compliant, and profitable drink production.