CIP Heat Exchangers for Fermentation Tank Interior Sterilization

Fermentation tanks accumulate yeast, bacteria, and protein residues that harbor spoilage organisms and phage. Our fully sanitary CIP heat exchangers supply exact hot water, caustic, and acid temperatures with high-velocity circulation — delivering validated sterilization, complete riboflavin coverage, and zero carryover between batches.

Critical Fermentation Tank Sterilization Applications

- Hot Water Sterilization: 185–195°F closed-loop water with precise temperature control for complete microbial kill on tank walls, top heads, and baffles.

- Caustic Protein Removal: Heated caustic circulation dissolves yeast, trub, and protein films from interior surfaces and spray-ball systems.

- Acid Tartrate & Mineral: Phosphoric/nitric acid loops remove beerstone, calcium oxalate, and mineral deposits with fully drainable exchangers.

- Spray-Ball Coverage: Supplies correctly heated solutions for 100 % riboflavin-validated wetting of tank interior and all shadow areas.

- Culture & Flavor Changeover: Complete CIP removes residual yeast, bacteria, and fruit/spice flavors between beer, kombucha, and yogurt runs.

- Phage Prevention: Validated sterilization cycles eliminate bacteriophage contamination risk in dairy and probiotic fermentation tanks.

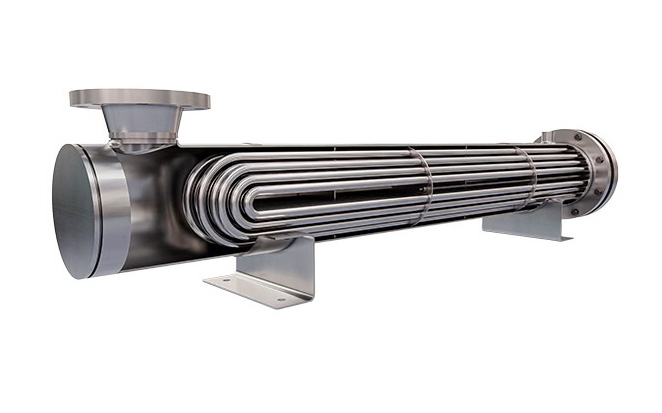

Shell & Tube

CIP Tank Exchangers

- Ideal for Hot Water Sets

- Double Tubesheet Options

- Fully Drainable Design

Plate & Frame

CIP Tank Exchangers

- High Regeneration Efficiency

- Compact & Fast Response

- Easy Inspection & CIP

The Critical Role of Sanitary CIP Heat Exchangers in Fermentation Tank Interior Sterilization

Fermentation tanks are breeding grounds for spoilage microbes and phage if not perfectly sterilized. Residual yeast, protein, and tartrates quickly become permanent contamination sources.

Our sanitary exchangers eliminate that risk with polished 316L surfaces (Ra = 32 µin), full drainability, and proven resistance to daily caustic, acid, and 195°F+ cycles — delivering the exact temperature and flow for validated sterilization and riboflavin coverage.

A major craft brewery eliminated recurring Brettanomyces issues after installing our hot water CIP systems. A global yogurt producer reduced phage incidents to zero with our precise caustic heating exchangers.

With 3-A certification, riboflavin & ATP validation, and decades of performance worldwide, our CIP heat exchangers are the trusted solution for safe, reliable fermentation tank sterilization.