CIP Heat Exchangers for Wine Fermentation Tank Cleaning

Wine tanks accumulate tartrates, yeast lees, grape solids, and spoilage organisms. Our fully sanitary, CIP-capable heat exchangers supply 185°F+ hot water, caustic, and acid solutions while withstanding aggressive cleaning cycles — delivering spotless tanks, zero cross-vintage carryover, and protection against Brettanomyces and acetic bacteria.

Key Wine Tank Cleaning Applications

- Hot Water Sanitization: Circulates 185–195°F water for tartrate removal and microbial kill.

- Caustic & Acid CIP Sets: Supplies heated caustic for lees/protein removal and acid for tartrate dissolution.

- Tank Cooling Loops: Rapid post-fermentation crash cooling with sanitary glycol exchangers.

- Red Wine Maceration Heating: Precise temperature control during fermentation with cleanable exchangers.

- Barrel & Line Cleaning: Hot water and PAA circulation for barrel rooms and transfer lines.

- Vintage Changeover: Full CIP eliminates grape variety and oak residues between harvests.

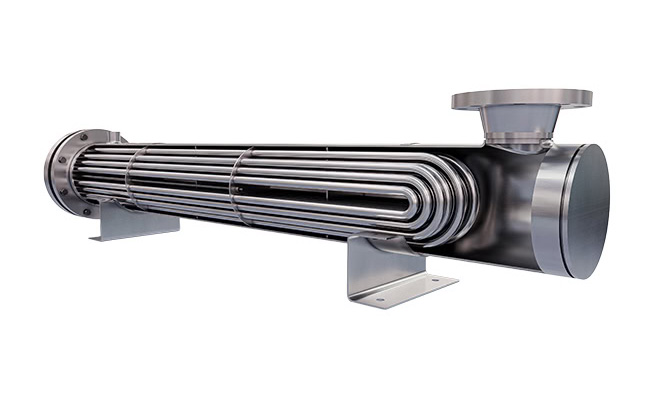

Shell & Tube

CIP Winery Exchangers

- Ideal for Hot Water & Steam Sets

- Double Tubesheet Options

- Fully Drainable & Tartrate Resistant

Plate & Frame

CIP Winery Exchangers

- Fast Response Cooling/Heating

- Compact for Small Wineries

- Easy Inspection & CIP

Why Sanitary CIP Heat Exchangers Are Essential for Wine Fermentation Tank Cleaning

Wine tanks that are not perfectly clean become breeding grounds for Brettanomyces, acetic bacteria, and tartrate buildup — ruining entire vintages. Manual cleaning is slow, dangerous, and inconsistent; only automated CIP with properly designed heat exchangers delivers reliable, repeatable results.

Our sanitary exchangers withstand daily hot caustic, tartaric acid, and 195°F water cycles while supplying precise heating/cooling for fermentation control. Polished 316L surfaces, full drainability, and no dead legs ensure zero residual grape solids or microbes remain.

A renowned Napa winery eliminated Brett contamination and reduced tank cleaning time by 70% after installing our hot water CIP exchangers. An Australian Shiraz producer achieved flawless vintage separation and zero tartrate issues with our fully CIP-capable cooling systems.

With proven performance in premium wineries worldwide, riboflavin-validated cleanability, and designs trusted by top vintners, our CIP heat exchangers are the professional choice for pristine fermentation tanks, consistent wine quality, and efficient winery operations.