CIP/SIP Heat Exchangers for Tank Sterilization

Process tanks (media, buffer, harvest) must achieve validated sterility without residue. Our ASME-BPE CIP/SIP heat exchangers supply pure steam for 121–135°C SIP, hot WFI circulation, and complete clean-in-place — delivering full interior sterilization, endotoxin removal, and zero cross-contamination risk.

Critical Tank Sterilization Applications

- Pure Steam SIP: 121–135°C pure steam delivery to tank interior, spray balls, and vents with double-tubesheet exchangers and full condensate drainage.

- Hot WFI Circulation: 80–90°C WFI loops for pre-SIP rinse and post-CIP sanitization with Ra = 15 µin electropolished surfaces.

- Spray Ball Coverage: Temperature-controlled pure steam/hot water ensures 100 % riboflavin-validated wetting of tank walls and top head.

- Media & Buffer Tanks: Complete SIP for nutrient-rich tanks with validated lethality and zero dead-leg designs.

- Harvest Tank Sterilization: Aggressive CIP/SIP removes cell debris and proteins from bioreactor harvest vessels.

- Endotoxin & Bioburden Control: Proven removal of pyrogens and microbes with full validation and documentation.

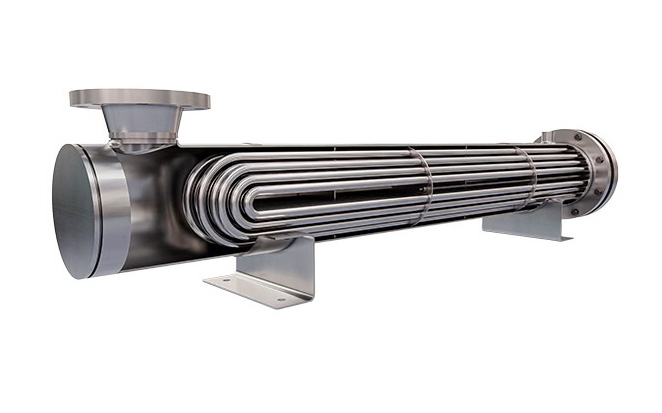

Shell & Tube

CIP/SIP Tank Exchangers

- Double Tubesheet ASME-BPE

- Pure Steam Compatible

- Fully Drainable SIP

Plate & Frame

CIP/SIP Tank Exchangers

- High Regeneration Efficiency

- Ra = 15 µin Electropolish

- Fast CIP & Validated SIP

The Critical Role of Sanitary CIP/SIP Heat Exchangers in Tank Sterilization

Process tanks — including media prep, buffer hold, harvest, and formulation vessels — are high-risk areas for bioburden, endotoxins, and cross-contamination if not perfectly sterilized. Non-compliant or poorly designed exchangers fail to deliver sustained pure steam or hot WFI, leading to sterility failures, batch loss, and regulatory issues.

Our ASME-BPE exchangers eliminate that risk with double-tubesheet designs for leak prevention, electropolished 316L surfaces (Ra = 15 µin), complete self-drainability, zero dead legs, and proven resistance to repeated 135°C pure steam SIP cycles — ensuring validated, reproducible tank interior sterilization with full condensate removal.

A global biologics producer achieved zero bioburden issues and extended campaign lengths after installing our pure steam systems. A major vaccine facility reduced SIP time 50% and improved energy efficiency with our high-regeneration plate exchangers for WFI circulation and tank heating.

Backed by third-party validation, comprehensive material traceability, weld documentation, and decades of reliable performance in the most demanding pharma and biotech plants worldwide, our CIP/SIP heat exchangers are the trusted industry standard for safe, compliant, and efficient tank sterilization.