Why CIP Heat Exchangers Are Essential in Yogurt Incubator Cleaning

Yogurt incubators are perfect breeding grounds for rogue cultures and phage. Only fully sanitary, 3-A certified CIP heat exchangers guarantee total removal of live cultures, milk proteins, and fruit residues — preventing flavor carryover, ensuring culture purity, and delivering validated cleaning between Greek, probiotic, and fruit-on-bottom runs.

Critical Yogurt Incubator Cleaning Applications

- Incubation Heating Loops: Precise 108–112°F water circulation with fully drainable, polished exchangers for uniform fermentation.

- Hot Water Sanitization: Supplies 185–195°F water for daily tank, line, and spray ball sanitization with zero dead legs.

- Post-Incubation Cooling: Rapid break cooling of set yogurt with sanitary plate exchangers to stop over-acidification.

- Fruit Prep Heating: Pasteurization of fruit preps before bottom-layer addition using fully CIP-capable systems.

- Greek Yogurt Separation: Pre-heating whey for separators with high-protein tolerant, cleanable exchangers.

- Flavor & Culture Changeover: Full CIP eliminates residual fruit, probiotics, and cultures between batches.

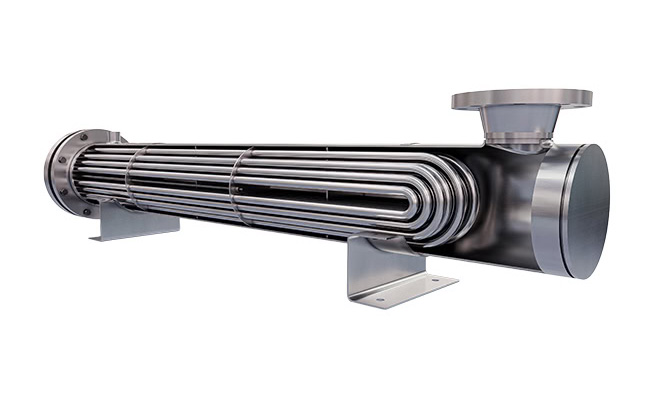

Shell & Tube

CIP Yogurt Exchangers

- Ideal for Hot Water Sets

- Double Tubesheet Options

- Fully Drainable & 3-A TPV

Plate & Frame

CIP Yogurt Exchangers

- Precise Incubation Control

- Fast Cooling Response

- Riboflavin & Culture Validated

Why CIP Heat Exchangers Are the Cornerstone of Yogurt Incubator Cleaning

Yogurt incubators that are not perfectly clean become phage factories and flavor nightmares. Residual cultures, fruit pieces, and milk proteins seed contamination and ruin entire batches. Only fully sanitary, 3-A certified CIP heat exchangers eliminate that risk — delivering polished 316L surfaces (Ra = 32 µin), complete drainability, and proven resistance to daily caustic, acid, and 195°F+ hot water cycles.

Our exchangers ensure pristine tanks between probiotic, Greek, fruit-on-bottom, and plain runs — protecting culture purity and preventing off-flavors while maintaining exact incubation temperatures.

A leading Greek yogurt producer eliminated phage incidents and reduced cleaning time 60% after installing our hot water CIP exchangers. A major stirred yogurt brand achieved zero flavor carryover and perfect culture performance with our fast-response plate systems.

With third-party verified (TPV) 3-A certification, riboflavin cleanability testing, full traceability, and decades of proven performance in the world’s top yogurt plants, our CIP heat exchangers are the trusted choice for flawless incubator cleaning, culture integrity, and consistent yogurt quality.