Why CIP Heat Exchangers Are Essential in Cheese Vat Equipment Sanitization

Cheese vats accumulate curd fines, whey proteins, and starter cultures that harbor Listeria and spoilage organisms. Only fully sanitary, 3-A certified CIP heat exchangers guarantee complete removal of residues and validated sterilization every cycle — preventing cross-contamination between cheddar, mozzarella, and gouda runs while meeting strict PMO and FDA requirements.

Critical Cheese Vat Sanitization Applications

- Milk Pre-Heating: Gentle thermization of cheese milk with fully drainable exchangers to avoid protein fouling (102 characters).

- Hot Water Sets: 185–195°F water loops for vat jacket heating and post-production sanitization cycles (99 characters).

- Whey Cooling: Rapid whey removal from curd with high-turbulence, CIP-capable exchangers (88 characters).

- Curd Washing: Temperature-controlled wash water systems with zero dead-leg, sanitary designs (94 characters).

- Culture Addition Lines: Sterile heating/cooling of starter and rennet lines with full CIP validation (101 characters).

- Vintage Changeover: Complete removal of previous curd residues and cultures between cheese types (96 characters).

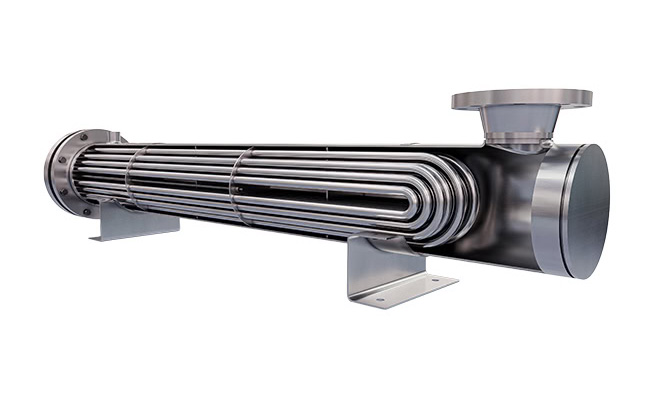

Shell & Tube

CIP Cheese Exchangers

- Double Tubesheet Protection

- Ideal for Hot Water Loops

- Full Drainability & 3-A TPV

Plate & Frame

CIP Cheese Exchangers

- High Regeneration Efficiency

- Wide-Gap for Whey & Curd

- Riboflavin & ATP Validated

Why CIP Heat Exchangers Are the Cornerstone of Cheese Vat Equipment Sanitization

Cheese vats are notorious for retaining curd particles, whey proteins, and starter cultures that harbor Listeria and spoilage microbes. A single unclean heat exchanger in the milk or water circuit can contaminate an entire day’s production. Only fully sanitary, 3-A certified CIP heat exchangers eliminate that risk — delivering polished 316L surfaces (Ra = 32 µin), complete drainability, no dead legs, and proven resistance to daily caustic, acid, and 185°F+ hot water cycles.

Our exchangers are trusted in the world’s largest cheddar, mozzarella, and gouda plants because they guarantee total removal of curd fines and cultures, validated log reductions, and zero flavor carryover between varieties — all while protecting delicate cheese milk proteins.

A major U.S. cheddar producer eliminated recurring Listeria positives and passed every PMO audit after installing our double-tubesheet hot water systems. An Italian mozzarella facility reduced vat cleaning time by 60% using our high-regeneration plate exchangers.

With third-party verified (TPV) 3-A certification, riboflavin cleanability testing, full traceability, and decades of proven performance, our CIP heat exchangers are the industry standard for uncompromising cheese vat sanitization, regulatory confidence, and operational excellence.