CIP Heat Exchangers for Bottled Water System Sanitization

Bottled water plants require the highest level of hygiene with zero tolerance for Pseudomonas, coliforms, or biofilm. Our fully sanitary, CIP-capable heat exchangers deliver 185°F+ hot water loops, ozone-compatible cooling, and complete clean-in-place performance — protecting membranes, carbon filters, and the entire bottling line.

Key Bottled Water Sanitization Applications

- Hot Water Sanitization Loops: Circulates 185–195°F water to sanitize pipes, tanks, and fillers daily.

- Ozone System Protection: Precise cooling of ozonated water to maintain dissolved ozone levels.

- Carbonated Water Chilling: Rapid cooling before CO2 injection for sparkling and flavored waters.

- RO & UF Membrane Protection: Pre-heating or cooling feed water to optimal filtration temperature.

- Filler & Cap Sanitization: Supplies hot water or steam condensate for filler sterilization.

- Flavor Changeover: Full CIP removes minerals and residual flavors between natural and flavored products.

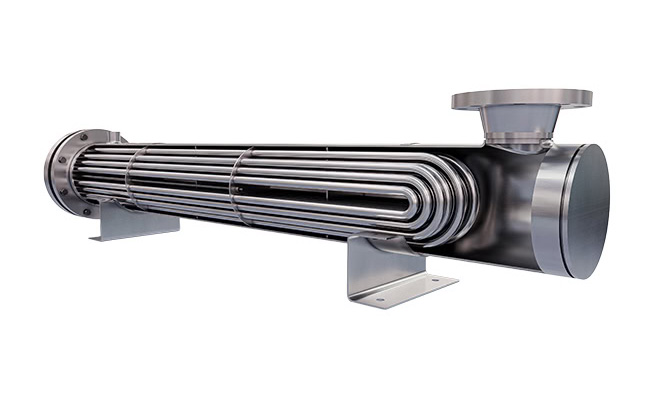

Shell & Tube

CIP Water Exchangers

- Ideal for High-Temp Hot Water Loops

- Double Tubesheet Leak Detection

- Fully Drainable & Ozone Compatible

Plate & Frame

CIP Water Exchangers

- High Efficiency & Compact Design

- Fast Heating/Cooling Response

- Easy Inspection & Validated CIP

Why Sanitary CIP Heat Exchangers Are Essential for Bottled Water System Sanitization

Bottled water has zero tolerance for contamination — a single biofilm event can trigger recalls and plant shutdowns. Non-CIP-capable or poorly designed heat exchangers are the leading source of Pseudomonas and coliform issues in bottling plants.

Our sanitary exchangers eliminate that risk with polished 316L surfaces, full drainability, no dead legs, and materials fully compatible with ozone, hot water, and chemical sanitizers. They enable daily 185°F+ sanitization loops, protect RO membranes from thermal shock, and ensure complete cleaning between natural and flavored water runs.

A major U.S. bottled water brand eliminated recurring microbial positives and passed every IBWA audit after installing our hot water sanitization exchangers. A global sparkling water producer reduced CIP water usage by 60% with our high-efficiency plate systems.

With riboflavin-validated cleanability, FDA/IBWA-compliant construction, and proven performance in the world’s largest bottled water plants, our CIP heat exchangers are the trusted foundation for safe, compliant, and efficient bottled water production.