CIP Heat Exchangers for Beverage Production

From breweries to soft drink and juice plants, sanitary CIP heat exchangers provide rapid heating and cooling of product and utilities while being fully cleanable — ensuring flavor consistency, microbial safety, and maximum uptime in high-speed beverage lines.

Applications

- Beer Wort Cooling: Rapidly drops hot wort from boil to pitching temperature using single- or two-stage plate or shell & tube exchangers.

- Pasteurization: Flash or tunnel pasteurization of beer, CSD, juice, and RTD beverages with precise PU control.

- Carbonated Soft Drinks: Pre-chills water and syrup before carbonation to improve CO2 absorption and reduce foaming.

- Juice & Tea Processing: HTST pasteurization and gentle cooling to preserve flavor and vitamins.

- Brite Tank & Cold Stabilization: Maintains precise cold-crash temperatures for clarity and shelf life.

- Glycol Utility Systems: Supplies chilled glycol loops for fermentation, crash cooling, and packaging halls.

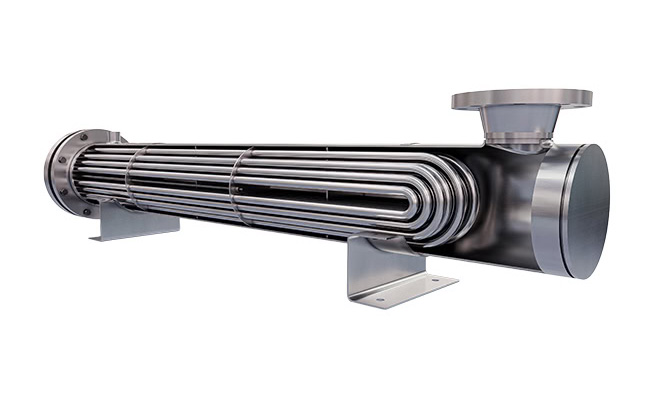

Shell & Tube

CIP Heat Exchangers

- Ideal for High-Pressure CO2 or Ammonia

- Robust for Brewery Steam/Wort

- Fully 3-A & Sanitary Welded

Plate & Frame

CIP Heat Exchangers

- High Turbulence & Fast Response

- Compact Footprint for Bottling Lines

- Easy Inspection & Gasket Replacement

The Benefits of Sanitary CIP Heat Exchangers in Beverage Production

Beverage plants operate at high speed with frequent flavor changeovers — making fully CIP-capable heat exchangers essential for maintaining hygiene, flavor integrity, and production efficiency.

Our 3-A compliant, fully drainable exchangers enable complete cleaning in minutes, eliminate flavor carryover (critical when switching from cola to lemon-lime or stout to lager), and support validated pasteurization processes.

A major U.S. craft brewery reduced cleaning time by 70% and doubled brews per day after installing our sanitary plate heat exchangers. A global soft-drink bottler achieved zero flavor crossover and passed every audit with our double-tubesheet shell & tube units.

With polished 316L surfaces, no dead legs, and designs proven in thousands of beverage plants worldwide, our CIP heat exchangers deliver the reliability, cleanability, and thermal performance today’s high-speed beverage lines demand.