CIP Heat Exchangers for Juice Processing Equipment

Juice is highly susceptible to Alicyclobacillus, yeast, and mold spoilage. Our fully sanitary, CIP-capable heat exchangers deliver precise HTST/UHT pasteurization and gentle cooling while guaranteeing complete cleanability — preserving vitamins, color, and fresh-squeezed taste in orange, apple, tropical, and functional juice products.

Key Juice Processing Applications

- Flash Pasteurization: Rapid heating and cooling for not-from-concentrate and premium juices.

- Hot Fill Processing: 185–195°F fill temperature for natural preservation of high-acid juices.

- Aseptic & ESL Systems: UHT sterilization for extended shelf life and ambient distribution.

- Pulp & Particulate Juices: Gentle handling of orange cells, aloe vera, and coconut pieces.

- Concentrate Reconstitution: Precise heating of water and concentrate before final blending.

- Flavor & Allergen Changeover: Full CIP removes citrus oils, berry residues, and allergens between runs.

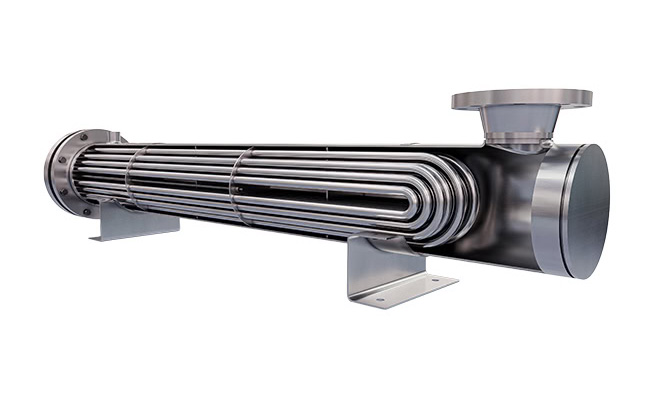

Shell & Tube

CIP Juice Exchangers

- Double Tubesheet Leak Protection

- Ideal for Hot Water & Steam

- Fully Drainable & 3-A Certified

Plate & Frame

CIP Juice Exchangers

- High Regeneration Efficiency

- Wide-Gap for Pulp & Cells

- Fast CIP & Validated Cleaning

Why Sanitary CIP Heat Exchangers Are Essential in Juice Processing Equipment

Juice is one of the most challenging beverages — high in natural sugars and acids, prone to heat-resistant molds and Alicyclobacillus. Non-CIP-capable exchangers are the primary source of spoilage recalls and off-flavor issues in the juice industry.

Our sanitary exchangers eliminate that risk with polished 316L surfaces, full drainability, no dead legs, and designs proven for aggressive caustic/acid CIP cycles. They deliver exact pasteurization units while preserving delicate vitamin C, color, and fresh-squeezed taste — critical for premium NFC and functional juices.

A global citrus processor eliminated Alicyclobacillus outbreaks and extended shelf life to 12 months using our UHT tubular systems. A leading apple juice brand reduced CIP time by 55% and achieved zero flavor carryover with our wide-gap plate pasteurizers.

With riboflavin-validated cleanability, 3-A certification where required, and proven performance in the world’s largest juice plants, our CIP heat exchangers are the trusted foundation for safe, high-quality, and profitable juice production.