CIP Heat Exchangers for Food Production Equipment

Modern food processing demands rapid product changeovers, allergen management, and validated cleaning. Our 3-A compliant, fully drainable CIP heat exchangers provide high-turbulence heating and cooling while guaranteeing complete removal of proteins, starches, fats, and particulates preventing cross-contamination and ensuring compliance with FSMA, GFSI, and BRC standards.

Key Food Production Applications

- Sauce & Soup Cooking: Direct or indirect steam heating with scraped-surface or tubular exchangers for viscous, particulate-laden products.

- UHT & Aseptic Processing: Sterilization of tomato-based products, dairy alternatives, and ready meals with tubular or plate systems.

- Fruit & Vegetable Puree: Gentle pasteurization and cooling to preserve color, flavor, and vitamins in jams, fillings, and baby food.

- Pet Food Processing: High-meat-content cooking and cooling with robust, fully CIP-capable shell & tube or corrugated tube designs.

- Ready Meals & Soups: Precise thermal treatment for multi-component products containing meat, pasta, or vegetables.

- Plant-Based & Alternative Proteins: Pasteurization of oat, almond, soy, and pea milk with minimal fouling and full allergen cleanability.

- Starch & Dressing Production: Gelatinization heating and cooling of mayonnaise, ketchup, and salad dressings.

- Egg & Liquid Egg Products: Safe pasteurization and rapid cooling of whole egg, yolk, and albumen while maintaining functionality.

- Bakery Fillings & Creams: Cooking and cooling of custard, fruit fillings, and chocolate compounds with scraped-surface technology.

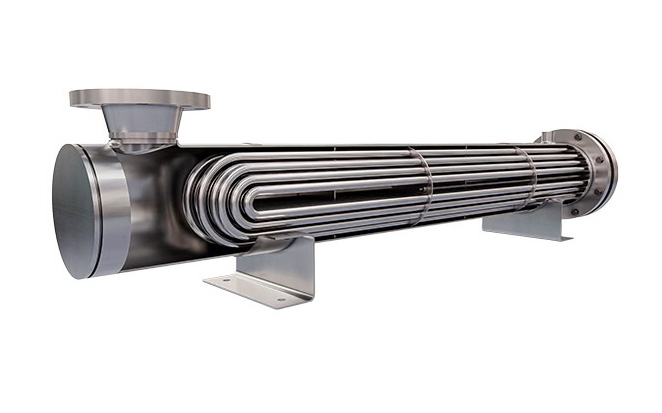

Shell & Tube

CIP Food Heat Exchangers

- Ideal for High-Viscosity Foods

- Corrugated/Multi-Tube Designs

- Handles Large Particulates

Plate & Frame

CIP Food Heat Exchangers

- High Turbulence, Low Fouling

- Wide-Gap for Fruit & Meat

- Fast Allergen Cleanability

Tube-in-Tube

CIP Food Heat Exchangers

- Perfect for Whole Fruit Pieces

- Monotube & Hairpin Styles

- Excellent CIP Cleanability

The Critical Role of Sanitary CIP Heat Exchangers in Food Production Equipment

Food production facilities face intense pressure for rapid product changeovers, strict allergen control, and zero tolerance for pathogens such as Listeria, Salmonella, and E. coli. Our sanitary CIP heat exchangers are purpose-built for complete cleanability featuring polished 316L surfaces (Ra = 32 ΅in), no dead legs, full drainability, and robust designs that withstand aggressive caustic, acid, and hot-water CIP cycles daily.

This ensures total removal of proteins, starches, sugars, and fats that cause fouling and harbor bacteria, while enabling validated allergen cleaning between runs (e.g., peanut butter to dairy-free, gluten to gluten-free). Whether heating tomato sauce, sterilizing plant-based milk, or cooling ready meals, our exchangers deliver food safety, flavor consistency, and extended run times.

A leading ready-meal producer eliminated allergen cross-contact and reduced CIP time by 50% after installing our wide-gap plate systems. A major pet food manufacturer achieved 24/7 continuous operation with zero microbial failures using our corrugated tube exchangers.

With 3-A certification where required, riboflavin-validated cleanability, full material traceability, and proven performance in thousands of food plants worldwide, our CIP heat exchangers are the trusted solution for modern food production equipment ensuring regulatory compliance, operational excellence, and consumer safety.