Understanding Clean-in-Place (CIP) Systems

CIP systems deliver repeatable, validated cleaning results while saving time, water, chemicals, and labor compared to manual cleaning. They are essential for maintaining product safety, preventing cross-contamination, and meeting regulatory standards like FDA, USDA, and 3-A.

- Cleaning Cycles: Typical sequence includes pre-rinse, caustic wash, rinse, acid wash, final rinse, and sanitization.

- Automation: PLC-controlled programs ensure consistent time, temperature, concentration, and flow.

- Water & Chemical Savings: Recovery tanks reuse rinse water and solutions, reducing consumption up to 50%.

- Safety: Eliminates confined-space entry and manual handling of hot chemicals.

- Validation: Built-in sensors monitor conductivity, temperature, and flow for audit-ready records.

- Flexibility: Single-use, multi-tank, or centralized systems fit any plant layout.

What is Clean-in-Place (CIP)?

Automated Sanitary Cleaning for Process Equipment

Clean-in-Place (CIP) is a proven method that cleans the interior surfaces of pipes, vessels, and equipment by circulating cleaning solutions at high velocity. It removes product residue, microorganisms, and allergens without taking the system apart—saving downtime and ensuring consistent hygiene.

- Reduces cleaning time by up to 75%

- Improves worker safety—no manual scrubbing

- Conserves water and chemicals through recovery

- Provides repeatable, validated results

- Prevents cross-contamination between batches

- Meets FDA, USDA, and 3-A sanitary standards

Key Benefits of Clean-in-Place Systems

CIP systems deliver faster cleaning, lower operating costs, and higher product safety. They are ideal for any process requiring frequent cleaning—dairy plants, breweries, juice lines, and pharmaceutical facilities. Proper design ensures full coverage, correct turbulence, and complete drainage for maximum effectiveness.

Modern CIP units feature automated controls, recovery tanks, and real-time monitoring to optimize water and chemical use while providing documentation for regulatory compliance.

How CIP Works

Cleaning solutions are pumped through spray balls, pipes, and equipment at velocities greater than 5 ft/s to create turbulence. Temperature, concentration, and time are precisely controlled. Conductivity sensors detect phase changes between rinse and detergent for efficient separation and recovery.

Types of CIP Systems

Single-use (lose solution after each cycle), reuse (recover caustic/acid), and multi-tank systems offer flexibility based on plant size and water restrictions. Centralized CIP serves multiple lines; decentralized units are placed near each process for faster return.

Design and Equipment Considerations

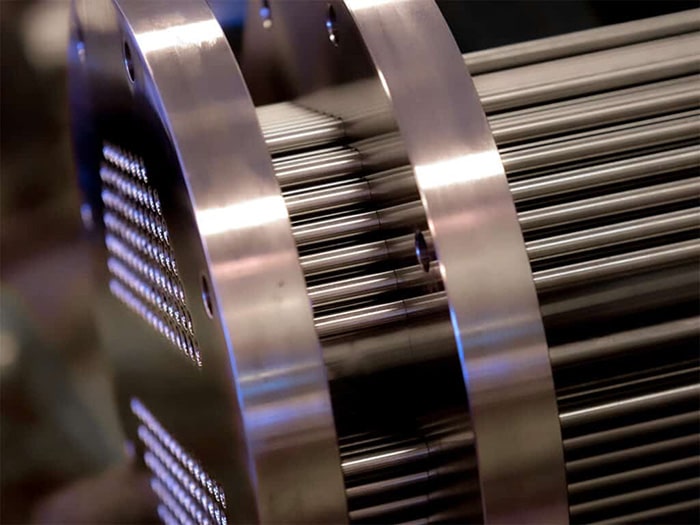

All process equipment must be CIP-compatible: sanitary welds, no dead legs, proper slopes for drainage, and spray devices sized for full coverage. Heat exchangers, valves, and pumps are selected with polished surfaces and cleanable seals.

Maintenance and Validation

Regular inspection of spray balls, pumps, and sensors ensures reliable performance. Validation includes riboflavin testing for coverage and microbial swabbing to confirm Sanitization. Automated logging simplifies audits.

Lifecycle Costs and ROI

Initial investment in CIP pays back quickly through reduced labor, water, chemical, and downtime costs. Most plants see ROI within 12–24 months, with ongoing savings in utilities and improved production uptime.

When to Implement CIP

Choose CIP for any hygienic process requiring daily or batch-to-batch cleaning. It is essential when manual cleaning is impractical, unsafe, or inconsistent. CIP is standard in dairy, beverage, prepared foods, and biotech industries.

Common FAQs

Clean-in-Place (CIP) is an automated cleaning process that circulates detergents, water, and sanitizers through process equipment without disassembly. Solutions flow at high velocity to remove soil and bacteria, followed by rinses to leave surfaces clean and ready for production.

Consider process soil type, water availability, production schedule, and regulatory requirements. Evaluate flow rates, temperature, chemical concentration, recovery needs, and equipment layout to ensure full coverage and drainage.

- Faster cleaning and higher production uptime

- Consistent, repeatable results

- Reduced labor and improved worker safety

- Lower water and chemical usage

- Prevents cross-contamination

Initial cost is higher than manual cleaning. Poorly designed equipment (dead legs, low flow) may not clean properly. Heavy soil loads may require pre-rinsing or manual pre-cleaning.

With proper maintenance, a CIP system can last 20+ years. Stainless steel construction, regular pump and valve service, and sensor calibration ensure long-term reliability.

Maintenance includes checking spray balls for blockages, calibrating conductivity and temperature sensors, inspecting pumps and valves, and verifying program logic. Regular validation confirms cleaning effectiveness.